إتقان عمليات آلات التحكم العددي بالحاسوب لتصنيع الأجزاء الداخلية للسيارات

لقد جعل تطور صناعة السيارات ماكينات القطع باستخدام الحاسب العددي (CNC) ضرورية في إنتاج مكونات داخلية للسيارات بدقة عالية وجودة ممتازة. ويتطلب تدريب المشغلين على استخدام هذه الماكينات المتطورة بشكل فعال نهجًا شاملاً يجمع بين المعرفة التقنية والمهارات العملية وبروتوكولات السلامة. يستعرض هذا الدليل العناصر الأساسية لتطوير مشغلين أكفاء لماكينات CNC خصيصًا لتصنيع الأجزاء الداخلية للسيارات.

المكونات الأساسية للتدريب

هندسة الماكينة والعمليات الأساسية

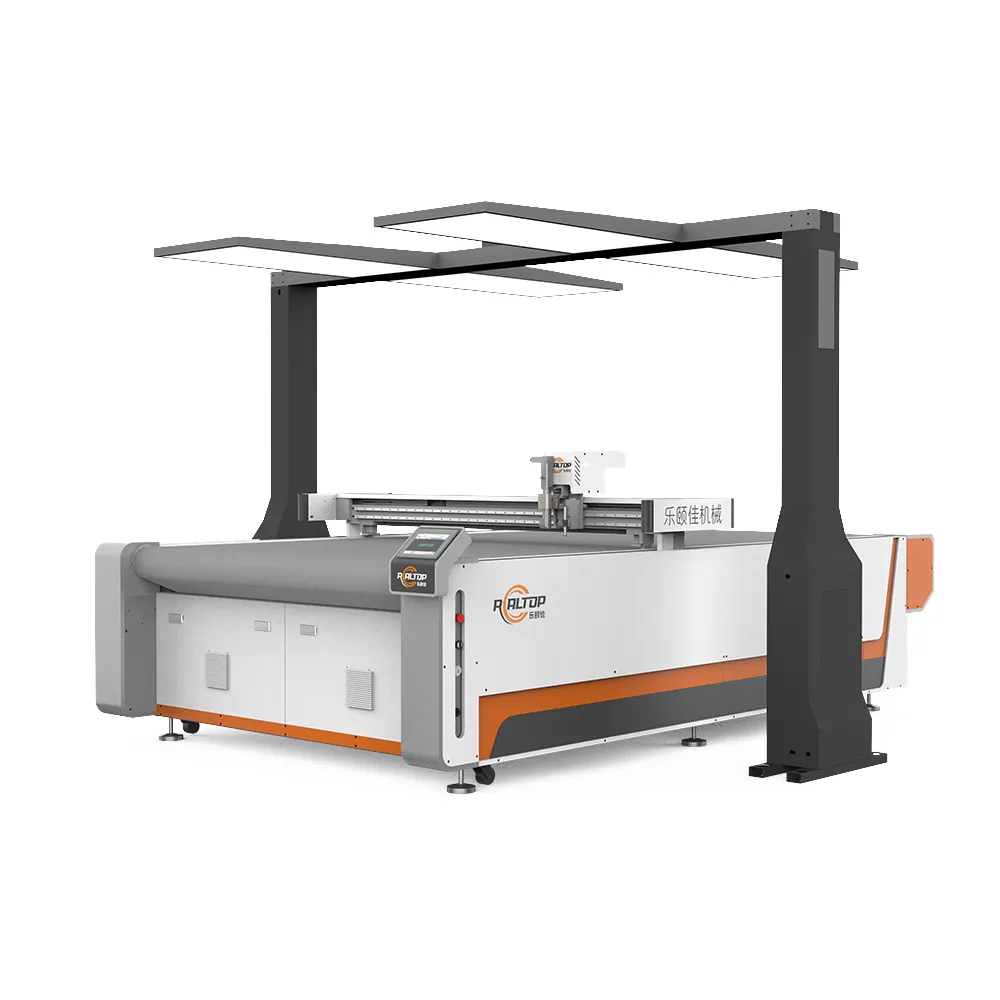

قبل البدء بالتدريب العملي، يجب أن يفهم المشغلون البنية الأساسية لماكينات القطع باستخدام الحاسب العددي (CNC). ويشمل ذلك معرفة المكونات الرئيسية للماكينة، مثل لوحة التحكم ورأس القطع وطاولة العمل وميزات السلامة. كما ينبغي أن يتعلم المشغلون العمليات الأساسية للماكينة، بما في ذلك إجراءات التشغيل، وإجراءات الإيقاف الطارئة، والفحوصات الروتينية للصيانة.

يجب أن يركز التدريب على العلاقة بين المكونات المختلفة للآلة وكيفية عملها معًا لتحقيق قص دقيق. إن فهم المبادئ الميكانيكية وراء آلات القص باستخدام التحكم العددي بالحاسوب (CNC) يساعد المشغلين على تشخيص المشكلات ومعالجتها بشكل أكثر فعالية والحفاظ على الأداء الأمثل أثناء عمليات الإنتاج.

واجهة البرنامج وأساسيات البرمجة

تعتمد آلات القص الحديثة التي تستخدم التحكم العددي بالحاسوب (CNC) اعتمادًا كبيرًا على أنظمة برمجية متطورة. يحتاج المشغلون إلى تدريب شامل على التنقل في واجهة الآلة، وتفسير رسومات التصميم بمساعدة الحاسوب (CAD)، وفهم أساسيات رمز G. ويشمل ذلك تعلُّم كيفية تحميل البرامج، وإجراء تعديلات طفيفة على معايير القص، والتحقق من دقة البرنامج قبل تنفيذه.

يجب أن تركز التمارين العملية على العمليات البرمجية الشائعة المستخدمة في تصنيع الديكورات الداخلية للسيارات، مثل التعرف على الأنماط، وتحسين استخدام المواد، وتعديل البرامج. هذه المهارات ضرورية للحفاظ على كفاءة الإنتاج وتقليل هدر المواد.

تقنيات معالجة وتحريك المواد

اختيار وتحضير المادة

تتطلب مكونات المقصورة الداخلية للسيارات استخدام مواد مختلفة، ولكل منها متطلبات قطع فريدة. يجب على المشغلين تعلُّم التعرف على المواد المختلفة، وفهم خصائصها، ومعرفة كيفية تأثير هذه الخصائص على معايير القطع. ويجب أن يشمل التدريب إجراءات التخزين الصحيحة للمواد، وطرق التعامل معها، وتقنيات الإعداد لضمان نتائج قطع مثالية.

يجب أن تتضمن الجلسات العملية تمارين في فحص المواد، وتحديد العيوب، والوضع الصحيح على طاولة القطع. تساعد هذه المعرفة في منع هدر المواد وضمان جودة متسقة في المنتجات النهائية.

معايير القطع والتحسين

يعتمد النجاح في عمليات القطع باستخدام التحكم العددي بالحاسوب (CNC) إلى حد كبير على اختيار المعلمات المناسبة للقطع. ويجب أن يفهم المشغلون كيف تؤثر عوامل مثل معدل التغذية، وسرعة القطع، واختيار الأداة على جودة القطع. وينبغي أن يشمل التدريب الخبرة العملية في تعديل هذه المعلمات حسب المواد المختلفة ومواصفات المكونات.

يجب إيلاء اهتمام خاص للتقنيات الخاصة بتحسين أنماط القطع لتعظيم استخدام المواد مع الحفاظ على معايير الجودة المطلوبة. ويشمل ذلك فهم مبادئ التجميع (Nesting) وكيفية تعديل تسلسلات القطع لتحقيق أقصى كفاءة.

مراقبة الجودة واستكشاف الأخطاء وإصلاحها

إجراءات فحص الجودة

تُعد مراقبة الجودة أمرًا بالغ الأهمية في تصنيع الواجهات الداخلية للسيارات. ويجب تدريب المشغلين على استخدام أدوات القياس وتقنيات الفحص للتحقق من دقة المكونات. ويشمل ذلك فهم مواصفات التحمل، وأداء الفحوصات البعدية، وتوثيق مقاييس الجودة.

يجب أن يُركّز التدريب على أهمية المراقبة المستمرة أثناء تشغيل الإنتاج وتعليم المشغلين كيفية تحديد العلامات المبكرة لمشكلات الجودة. يساعد هذا النهج الاستباقي في الحفاظ على جودة المنتجات بشكل متسق ويقلل من معدلات الهالك.

المشاكل الشائعة والحلول

حتى ماكينات القطع باستخدام التحكم الرقمي بالحاسوب (CNC) التي تُصانَ جيدًا قد تواجه مشكلات تشغيلية. يحتاج المشغلون إلى تدريب على تحديد المشكلات الشائعة وتطبيق الحلول المناسبة. ويشمل ذلك فهم رسائل الخطأ، وملاحظة السلوك غير الطبيعي للماكينة، ومعرفة الوقت الذي يجب فيه طلب الدعم الفني.

يجب أن تحاكي تمارين استكشاف الأخطاء وإصلاحها العملية المشكلات الواقعية التي قد يواجهها المشغلون، مما يساعدهم على اكتساب الثقة في التعامل مع مختلف المواقف بشكل مستقل.

بروتوكولات السلامة وأفضل الممارسات

معايير السلامة في مكان العمل

يُعد التدريب على السلامة أمرًا بالغ الأهمية عند تشغيل ماكينات القطع باستخدام الحاسب (CNC). يجب أن يفهم المشغلون جميع بروتوكولات السلامة ذات الصلة، بما في ذلك الاستخدام السليم لمعدات الحماية الشخصية، وإجراءات الطوارئ، وميزات سلامة الماكينة. وتساعد التدريبات المنتظمة على السلامة والتحديثات المستمرة في الحفاظ على مستوى عالٍ من الوعي والاستعداد.

يجب أن يشمل التدريب اعتبارات السلامة الخاصة بالتعامل مع المواد والأدوات المختلفة المستخدمة في تصنيع مكونات داخلية السيارات. ويشمل ذلك متطلبات التهوية المناسبة، وسلامة التعامل مع المواد، وإجراءات الاستجابة للطوارئ.

إجراءات الصيانة وبروتوكولات الغرف النظيفة

تُعد إجراءات الصيانة السليمة ضرورية لضمان عمر أطول للماكينة وأداءً أمثل. ينبغي أن يتعلم المشغلون المهام الروتينية للصيانة، وطرق التنظيف، وكيفية الحفاظ على بيئة غرفة نظيفة عند الحاجة. ويشمل ذلك فهم جداول الصيانة، والتقنيات الصحيحة للتنظيف، ومتطلبات التوثيق.

يجب أن يُركّز التدريب على أهمية الفحص المنتظم للمعدات والاحتفاظ بسجلات صحيحة للأنشطة الصيانية. وهذا يساعد في منع توقف العمل المفاجئ ويضمن جودة إنتاج مستمرة.

الأسئلة الشائعة

ما المؤهلات المطلوبة لتصبح مشغلًا لماكينة قطع CNC؟

رغم أن المتطلبات تختلف حسب جهة العمل، فإن معظم مشغلي ماكينات قطع CNC يحتاجون إلى شهادة ثانوية عامة أو ما يعادلها، ومهارات أساسية في الحاسوب، وقدرة ميكانيكية. وغالبًا يُفضّل الحصول على تدريب تقني أو شهادة في عمليات CNC، كما يقدّم كثير من أرباب العمل برامج تدريب شاملة أثناء العمل.

كم يستغرق عادةً تدريب مشغل جديد لماكينة قطع CNC؟

عادةً يستغرق التدريب الأساسي من 3 إلى 6 أشهر، حسب تعقيد العمليات وخبرة المشغل السابقة. ولكن قد يستغرق اكتساب الكفاءة الكاملة في جميع جوانب تصنيع الأجزاء الداخلية للسيارات ما يصل إلى سنة من الخبرة العملية.

ما هي المهارات الأكثر أهمية لمشغلي آلات القطع باستخدام التحكم العددي الحاسوبي (CNC) الناجحين؟

يحتاج المشغلون الناجحون إلى اهتمام شديد بالتفاصيل، وقدرات جيدة على حل المشكلات، ومهارات حاسوبية أساسية، والكفاءة الميكانيكية. كما ينبغي أن يتمتعوا بمهارات تواصل جيدة، نظرًا لأنهم غالبًا ما يعملون كجزء من فريق ويحتاجون إلى الإبلاغ عن المشكلات أو القضايا بشكل فعال.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES