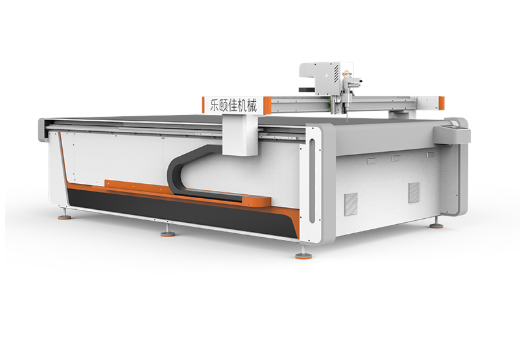

Manufacturing car interiors requires getting three things right: precision, efficiency, and making sure materials aren't wasted. Think about all those complicated shapes needed for seats, dashboard parts, door panels, and fabric coverings. Getting these right demands serious accuracy at every stage. That's where CNC cutting machines step in for car interior production. These industrial cutters bring advanced tech to bear on the job, letting factories churn out consistently good quality parts even when dealing with complex geometries. The machines work fast while maintaining tight tolerances, which matters a lot when fitting together different interior components without gaps or misalignment issues down the line.

But how do you choose the right CNC cutting machine for your specific car interior production needs? In this article, we explore the key factors to consider when selecting the perfect CNC cutting machine for car interiors, including material compatibility, cutting speed, and automation features.

Precision and Accuracy for Automotive Parts

Why Precision Matters in Car Interiors

Inside cars there are lots of parts needing really accurate cuts to make everything fit just right. We're talking about things like seats, cushioning materials, fabrics, leather trim, and various plastics. Even small mistakes during cutting can cause problems down the road - parts might not line up properly, show visible flaws, or simply refuse to fit together at all. This is particularly noticeable in premium vehicles where customers expect nothing but perfection. The CNC Cutting Machine used specifically for car interior work delivers exceptional accuracy. It makes sure each component matches exactly what's needed, whether dealing with simple shapes or those complicated designs that look almost impossible to manufacture.

Whether itâs for cutting fabric for seats or shaping intricate plastic panels for dashboards, these machines maintain tight tolerances that are critical to the overall quality and functionality of the car's interior.

The Role of Advanced Technology

Today's CNC cutting machines used for car interior manufacturing come equipped with some pretty impressive tech options including lasers, water jets, and those vibrating blade systems. What makes these so valuable is their ability to cut materials extremely accurately while keeping things looking neat and tidy without warping much. Take laser cutting as an example it works wonders because there's no actual touching involved during the process. This means sensitive materials like fine fabric upholstery or genuine leather stay intact and undamaged throughout production runs.

Material Compatibility and Versatility

A Wide Range of Materials

Car interior manufacturing involves working with all sorts of materials these days - think fabrics, foams, genuine leather, synthetic rubbers, composite panels, and countless plastic varieties. When looking at equipment options, finding a CNC cutting system that works across different material types becomes really important for shops wanting flexibility in their production processes. Modern CNC systems designed specifically for automotive interiors can tackle most common materials without much hassle, which means manufacturers save space and money instead of maintaining separate machines for each type of material they work with.

For example, if your production line involves cutting automotive upholstery, your CNC cutting machine should be able to handle both soft materials like leather and more rigid materials like plastic trim without compromising quality. Itâs important to select a machine that offers adaptability to meet different design specifications.

Ability to Handle Complex Shapes

When designing parts for car interiors, manufacturers frequently need to work with complicated shapes and exact cutouts that fit perfectly. Good CNC cutting machines handle these tricky patterns without breaking a sweat something that would take forever and require tons of effort if done manually. From simple tasks like trimming seat covers to more complicated jobs involving air vent assemblies or dashboard inserts, these specialized cutting tools give automotive designers real flexibility when dealing with all sorts of geometric challenges that come up during production runs.

Cutting Speed and Efficiency

Faster Turnaround Times

The automotive manufacturing world is pretty cutthroat these days, with companies constantly racing against the clock to shorten lead times and hit tight production deadlines. CNC cutting machines designed specifically for car interiors have become real game changers here. They slice through materials at impressive speeds while still maintaining precise cuts that matter for quality control. Factories using these machines report processing massive amounts of foam, fabric, and plastic components much faster than traditional methods allowed. This speed boost lets auto makers move products through assembly lines quicker, which means they can actually keep up when consumer demand spikes unexpectedly.

Faster cutting speeds also contribute to more efficient operations, allowing manufacturers to produce more parts in less time. By reducing the time required for each cut, these machines help companies improve overall productivity and meet deadlines more effectively.

Minimizing Downtime with Automation

Modern CNC cutting machines really rely on automation as one of their main selling points. These systems come equipped with things like automatic tool changers, self-feeding materials, and built-in quality checks that let them run basically on their own most of the time. This cuts down on both downtime when something goes wrong and the need for workers to constantly monitor operations. What's great about all this automation? Production keeps going without hiccups even late at night or early morning when nobody's around. Manufacturers find they can crank out way more parts than before simply because the machines don't need constant attention anymore.

Cost Efficiency and Long-Term Investment

Reducing Material Waste

One big problem facing car interior makers these days? Material waste. When parts aren't cut properly on the factory floor, tons of expensive raw materials just end up in landfills instead of becoming dashboard components or seat covers. That's where CNC cutting machines come into play specifically for automotive interiors. These machines slash waste because they cut materials with laser-like precision while getting the most out of each sheet or panel. The real magic happens through advanced layout software though. Manufacturers can now arrange all those different shapes and sizes so nothing goes to waste. Some shops report saving hundreds of dollars per batch simply by optimizing their cutting patterns this way.

By reducing scrap and improving material yield, these machines contribute to cost savings over time, making them a smart investment for companies looking to maintain profitability.

Low Maintenance and Durability

Car interior CNC cutting machines are constructed to handle serious wear and tear while needing surprisingly little upkeep. Most shops find that routine checks every few months keep these systems running smoothly for decade after decade. What makes these machines so reliable? Their robust construction allows auto part producers to maintain steady output without worrying about unexpected downtime or expensive fixes down the road. Some manufacturers report getting over 15 years out of their initial investment when they stick to manufacturer recommended maintenance schedules.

Moreover, the longevity of these machines means that manufacturers will see a high return on investment over time, as they are designed to provide consistent performance and high-quality cuts for years.

Conclusion â The Right CNC Cutting Machine for Car Interiors

Choosing the right CNC Cutting Machine for Car Interiors is a crucial decision for manufacturers who wish to enhance production efficiency, improve precision, and deliver high-quality components for automotive interiors. Factors like material compatibility, cutting speed, automation, and cost efficiency play an important role in the selection process.

Investing in proper CNC cutting equipment allows manufacturers to produce car interiors that consistently hit quality benchmarks for fit and function. For companies making everything from premium automotive trim pieces to standard issue dashboard components, selecting the appropriate CNC cutting system makes a real difference in production efficiency. The right machine setup streamlines operations while maintaining dimensional accuracy across batches. Many shops report reduced waste rates and faster turnaround times after upgrading their cutting capabilities. This translates into better margins without compromising on product specifications required by OEMs and aftermarket clients alike.

FAQ

What types of materials can a CNC cutting machine handle for car interiors?

A CNC cutting machine can handle a wide variety of materials used in car interiors, including fabric, leather, foam, plastics, rubber, and composites.

How does CNC cutting technology ensure precision in car interior components?

CNC cutting technology uses advanced systems like laser, water jet, and oscillating blades to achieve ultra-fine accuracy and clean cuts, ensuring precise and consistent components for car interiors.

How does a CNC cutting machine improve production efficiency?

CNC cutting machines operate at high speeds and offer automated processes, which help reduce production time, minimize downtime, and increase overall productivity.

Are CNC cutting machines suitable for complex shapes and custom designs?

Yes, CNC cutting machines are highly versatile and can easily handle intricate and complex shapes, making them ideal for the customized and detailed components required in car interiors.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES