Revolutionizing Automotive Interior Manufacturing Through Advanced CNC Technology

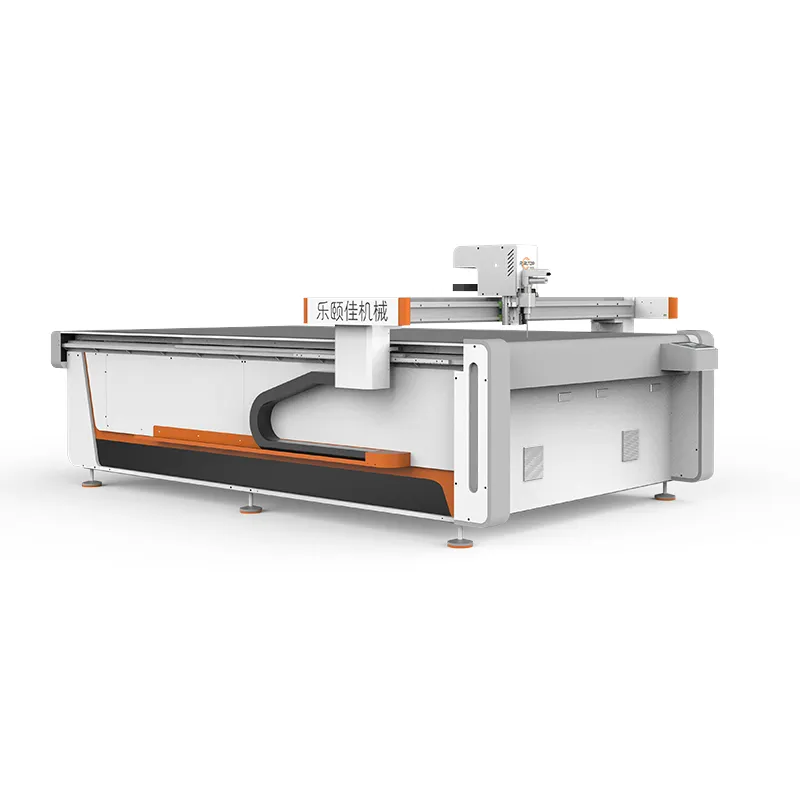

The automotive industry has witnessed a remarkable transformation in how vehicle interiors are manufactured, with car interiors CNC cutting machines emerging as indispensable tools in modern production facilities. These sophisticated systems have fundamentally changed the way manufacturers approach interior component design, production efficiency, and quality control. The precision and versatility offered by CNC technology have made it a cornerstone of automotive interior manufacturing, enabling producers to meet increasingly demanding customer expectations while maintaining cost-effectiveness.

As vehicles become more sophisticated and consumer preferences evolve, the role of CNC cutting machines in creating car interiors has become increasingly critical. These advanced systems enable manufacturers to achieve unprecedented levels of accuracy and consistency while maintaining the flexibility to adapt to changing design requirements and market demands.

Core Applications in Automotive Interior Production

Seat Component Manufacturing

One of the most significant applications of car interiors CNC cutting machines lies in seat production. These machines excel at cutting various materials used in modern automotive seating, from leather and fabric covers to foam padding and structural components. The precision of CNC technology ensures that each piece meets exact specifications, crucial for both aesthetic appeal and safety compliance.

Advanced CNC systems can seamlessly handle multiple layers of materials, performing complex cutting patterns that would be virtually impossible to achieve consistently through manual methods. This capability is particularly valuable when creating contoured seating designs that require precise matching of patterns and materials across different sections.

Dashboard and Console Elements

The dashboard and center console represent another critical application area where car interiors CNC cutting machines prove their worth. These components often require intricate cutouts for instruments, displays, and control panels, demanding extreme precision to ensure proper fit and functionality. CNC technology enables manufacturers to create these complex shapes with consistent accuracy, reducing waste and assembly time.

Modern vehicles increasingly feature sophisticated dashboard designs with integrated lighting elements and decorative patterns. CNC cutting machines excel at creating the precise channels and mounting points needed for these features, ensuring perfect alignment and professional finishing in the final assembly.

Material Versatility and Processing Capabilities

Synthetic Material Processing

Car interiors CNC cutting machines demonstrate remarkable versatility in handling various synthetic materials commonly used in modern vehicles. From vinyl and synthetic leather to advanced composites, these machines can process materials with different thicknesses and properties while maintaining consistent quality. The ability to adjust cutting parameters precisely ensures optimal results across diverse material types.

The technology's capability to handle multiple layers simultaneously makes it particularly valuable for producing components with complex laminated structures, such as door panels and headliners. This multilayer processing ability significantly reduces production time while ensuring perfect alignment between layers.

Natural Material Handling

When working with natural materials like genuine leather, car interiors CNC cutting machines offer unparalleled precision and material optimization. The technology's advanced nesting capabilities help maximize material usage, particularly important when working with expensive natural materials. Sophisticated scanning systems can identify flaws or variations in natural materials, ensuring that cuts are optimized to avoid imperfections.

The machines' ability to maintain consistent cutting quality across varying material thicknesses and textures is particularly valuable when working with natural materials, which often exhibit more variation than their synthetic counterparts. This consistency helps maintain high quality standards while minimizing waste and production costs.

Enhanced Production Efficiency and Quality Control

Automated Workflow Integration

Modern car interiors CNC cutting machines seamlessly integrate into automated production workflows, significantly enhancing manufacturing efficiency. These systems can be programmed to work continuously, maintaining consistent output quality while reducing labor requirements. The integration capabilities extend to computer-aided design (CAD) systems, allowing for rapid implementation of design changes and new product specifications.

The automation potential of these machines extends beyond mere cutting operations. Advanced systems can include automatic material feeding, pattern recognition, and quality control functions, creating a comprehensive production solution that minimizes human intervention while maximizing output quality.

Quality Assurance Features

Quality control is fundamentally enhanced through the use of car interiors CNC cutting machines. These systems typically incorporate advanced monitoring and verification features that ensure each cut meets specified tolerances. Real-time feedback systems can detect and correct potential issues before they affect product quality, maintaining consistent standards throughout production runs.

The precision and repeatability of CNC technology contribute significantly to reduced error rates and improved overall product quality. This consistency is particularly important in automotive applications, where components must meet strict safety and quality standards while maintaining aesthetic appeal.

Future Trends and Technological Advancement

Smart Manufacturing Integration

The future of car interiors CNC cutting machines lies in their increasing integration with smart manufacturing systems. Industry 4.0 principles are driving the development of more connected and intelligent cutting solutions that can communicate with other production systems, optimize operations in real-time, and adapt to changing production requirements automatically.

These advancements are leading to more efficient resource utilization, reduced downtime, and improved production planning capabilities. The integration of artificial intelligence and machine learning algorithms is enabling predictive maintenance and self-optimizing cutting parameters, further enhancing operational efficiency.

Sustainability and Resource Optimization

Environmental considerations are driving innovations in car interiors CNC cutting machines, with newer systems focusing on energy efficiency and material optimization. Advanced nesting algorithms and cutting strategies are being developed to minimize waste, while more efficient drive systems reduce energy consumption during operation.

The ability to process recycled and sustainable materials is becoming increasingly important, with manufacturers developing new cutting technologies specifically optimized for eco-friendly materials. This trend aligns with the automotive industry's broader move toward more sustainable production methods.

Frequently Asked Questions

How do car interiors CNC cutting machines improve production efficiency?

These machines enhance efficiency through automated operations, precise cutting capabilities, and integration with digital design systems. They reduce material waste, minimize human error, and can operate continuously with consistent quality, significantly improving overall production throughput and cost-effectiveness.

What materials can be processed using automotive interior CNC cutting systems?

Car interiors CNC cutting machines can process a wide range of materials including leather, vinyl, fabric, foam, composites, and various synthetic materials. They can handle multiple layers simultaneously and adjust cutting parameters to suit different material properties and thicknesses.

How do CNC cutting machines contribute to quality control in automotive interior manufacturing?

These machines provide consistent, precise cuts that meet exact specifications, incorporate real-time monitoring systems, and maintain quality standards across production runs. Their automated nature eliminates human error variables, while integrated quality control features ensure compliance with automotive industry standards.

Table of Contents

- Revolutionizing Automotive Interior Manufacturing Through Advanced CNC Technology

- Core Applications in Automotive Interior Production

- Material Versatility and Processing Capabilities

- Enhanced Production Efficiency and Quality Control

- Future Trends and Technological Advancement

- Frequently Asked Questions

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES