The Revolutionary Impact of Automated Leather Processing

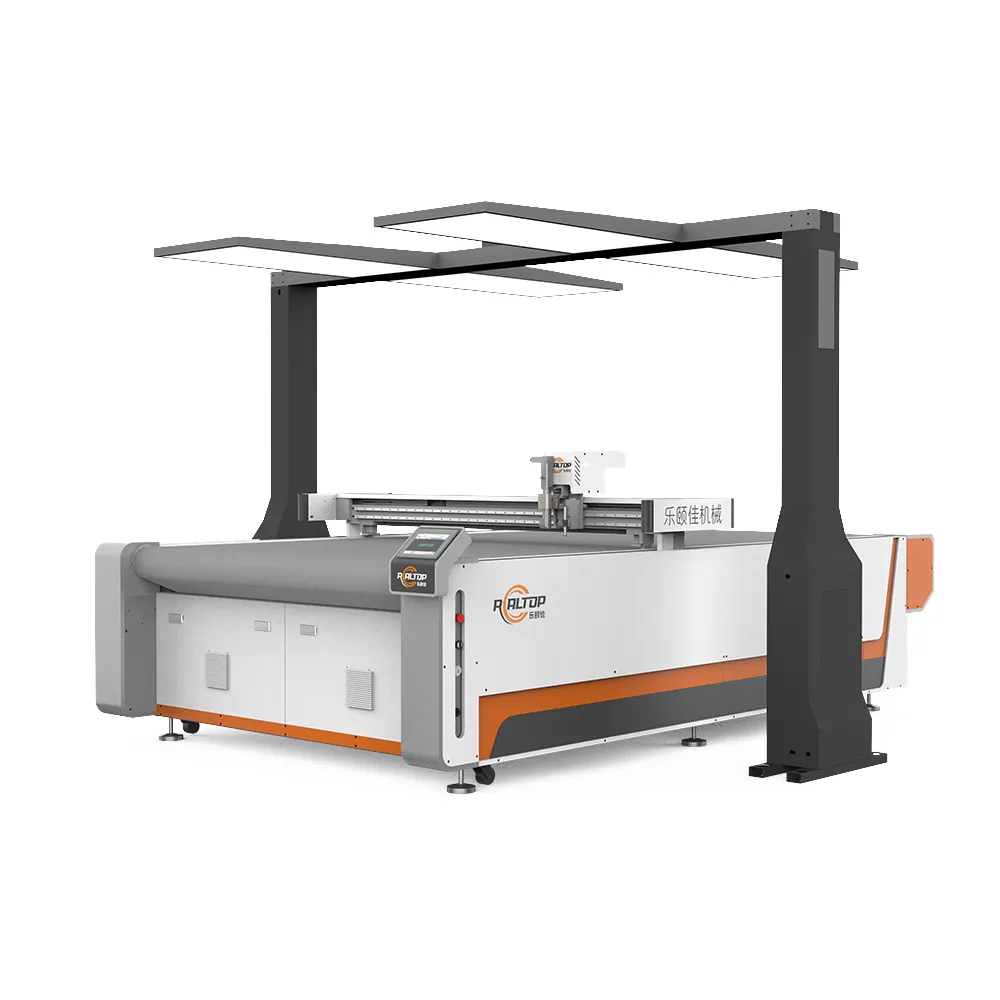

The leather industry has witnessed a dramatic transformation with the integration of leather cutting machines into manufacturing processes. These sophisticated pieces of equipment have revolutionized how businesses approach leather goods production, offering unprecedented precision, efficiency, and versatility. From luxury fashion houses to automotive upholstery manufacturers, the adoption of automated cutting technology has become a defining factor in maintaining competitive advantage and meeting modern production demands.

Key Industries Transformed by Automated Leather Cutting

Fashion and Luxury Goods Manufacturing

In the fashion industry, leather cutting machines have become indispensable tools for creating high-end products with consistent quality. Designer brands utilize these machines to produce everything from handbags to wallets, shoes, and accessories. The precision offered by automated cutting systems ensures that each piece meets exact specifications, reducing material waste and maintaining the highest standards of craftsmanship.

These machines excel at handling intricate patterns and complex designs that would be challenging to execute consistently by hand. Fashion houses can now produce detailed leather cutouts, decorative elements, and perfectly matched components with remarkable accuracy. This level of precision is particularly crucial when working with expensive exotic leathers where mistakes can be costly.

Automotive Interior Production

The automotive sector represents one of the largest applications for leather cutting machines. Vehicle interiors require numerous precisely cut leather components for seats, door panels, dashboards, and steering wheel covers. Modern automated cutting systems can process multiple layers of leather simultaneously, significantly increasing production efficiency while maintaining strict quality standards.

Automotive manufacturers particularly value the ability of these machines to optimize material usage through intelligent nesting algorithms. This technology allows them to maximize the number of usable pieces from each hide while accounting for natural variations and defects in the leather, resulting in substantial cost savings and reduced waste.

Advanced Features Driving Industry Adoption

Precision Cutting Technology

Modern leather cutting machines incorporate sophisticated cutting mechanisms that can achieve exceptional accuracy down to fractions of a millimeter. This precision is achieved through advanced sensor systems and computer-controlled cutting heads that maintain consistent pressure and cutting depth throughout the process. The result is clean, precise edges that require minimal finishing work.

These machines also feature automatic tool changing capabilities, allowing them to switch between different cutting tools for various leather thicknesses and types. This versatility enables manufacturers to process everything from soft, delicate leathers to tough, heavy-duty materials without manual intervention.

Digital Pattern Integration

The integration of CAD/CAM software with leather cutting machines has revolutionized pattern making and production planning. Designers can create and modify patterns digitally, then seamlessly transfer them to the cutting system. This digital workflow eliminates the need for physical templates and allows for rapid design iterations and customization.

Advanced nesting software optimizes pattern placement on leather hides, considering grain direction, stretch characteristics, and quality zones. This intelligent material utilization can significantly reduce waste, sometimes achieving material savings of up to 30% compared to manual cutting methods.

Productivity and Efficiency Benefits

Streamlined Production Processes

Leather cutting machines dramatically reduce production time compared to traditional manual cutting methods. A single machine can often match the output of multiple skilled craftspeople while maintaining consistent quality throughout long production runs. This increased efficiency allows manufacturers to meet tight deadlines and handle larger order volumes with confidence.

The automation of the cutting process also reduces the physical strain on workers, allowing them to focus on higher-value tasks such as quality control and final assembly. This reallocation of human resources leads to improved overall productivity and better working conditions.

Quality Control and Consistency

Automated cutting systems incorporate advanced quality control features that ensure consistent results across production runs. Built-in cameras and sensors can detect material defects, grain patterns, and thickness variations, automatically adjusting cutting parameters to maintain optimal results. This level of control is particularly valuable when working with natural leather, where material properties can vary significantly.

The ability to maintain precise specifications throughout production runs is crucial for manufacturers who must meet strict quality standards, especially in industries like automotive and aerospace where components must conform to exact tolerances.

Environmental and Economic Impact

Sustainable Manufacturing Practices

Modern leather cutting machines contribute significantly to sustainable manufacturing practices. By optimizing material usage and reducing waste, these systems help manufacturers minimize their environmental footprint. The precision cutting capabilities ensure that maximum value is extracted from each leather hide, reducing the overall demand for raw materials.

Additionally, many modern machines feature energy-efficient designs and can be integrated into digital manufacturing systems that optimize resource usage across entire production facilities. This comprehensive approach to sustainability helps companies meet increasingly stringent environmental regulations while improving their bottom line.

Cost Reduction and ROI

While the initial investment in leather cutting machines can be substantial, the long-term economic benefits are compelling. Reduced material waste, increased productivity, and lower labor costs contribute to a strong return on investment. Manufacturers typically report significant cost savings within the first year of implementation, particularly in high-volume production environments.

The reduction in material waste alone can justify the investment, especially when working with expensive leathers. When combined with lower labor costs and increased production capacity, the economic advantages become even more apparent.

Frequently Asked Questions

What types of leather can be processed by automated cutting machines?

Modern leather cutting machines can handle virtually any type of leather, from soft and delicate materials to thick, rigid hides. This includes full-grain leather, split leather, suede, and exotic leather types. The machines can be configured with different tools and cutting parameters to accommodate varying material properties.

How do leather cutting machines compare to manual cutting methods?

Automated leather cutting machines offer superior precision, consistency, and efficiency compared to manual cutting. While skilled craftspeople can achieve high-quality results, machines can maintain this quality level continuously across large production runs while significantly reducing material waste and processing time.

What maintenance is required for leather cutting machines?

Regular maintenance typically includes cleaning the cutting surface, replacing cutting tools when worn, calibrating sensors, and updating software systems. Most modern machines have built-in diagnostics that alert operators to maintenance needs, helping to prevent unexpected downtime and ensure optimal performance.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES