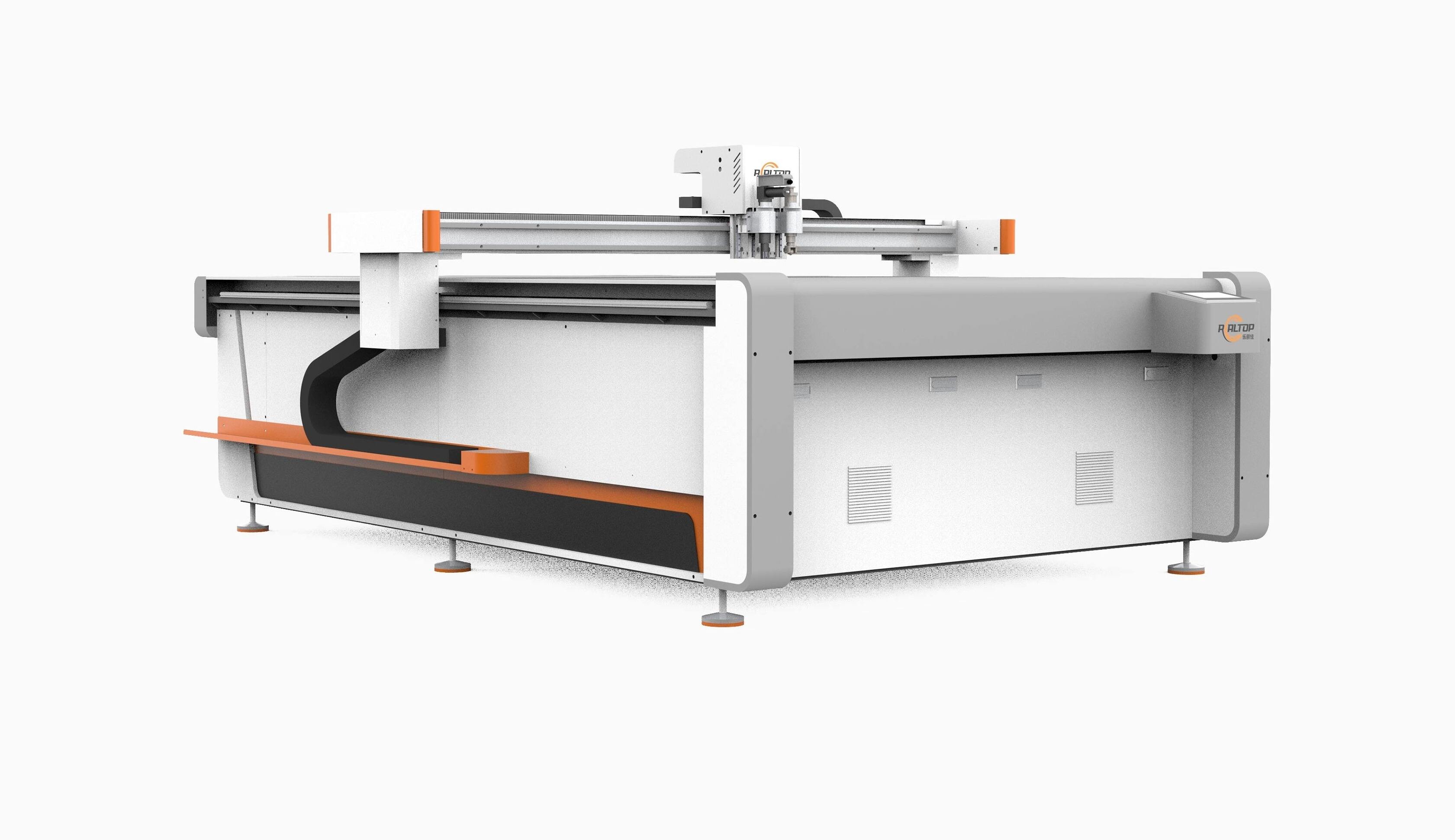

The advertising world is getting tougher by the day, so companies need to produce top-notch printed stuff without breaking the bank on time and resources. When talking about banners, posters, signage, and all those marketing prints, how clean and accurate the cuts are makes all the difference between looking pro and just okay. That's where modern cutting machines come into play for ad printing shops everywhere. These devices have changed things quite a bit for businesses making promotional materials. They save money in the long run because they cut faster and waste less material. Plus, the end results look much better since the edges are smoother and more precise than what older methods could achieve. Many small print shops report being able to take on bigger projects after investing in good cutting equipment.

This article explores the key benefits of using Advertising Printings Cutting Machines in the advertising industry and why they have become an indispensable tool for modern print shops.

Precision and Accuracy

Ensuring Consistent Cuts

What makes advertising printings cutting machines so valuable? They deliver pinpoint accuracy for every single cut made. Old school cutting techniques depend heavily on human hands, which means there's always room for mistakes when dealing with intricate patterns or big projects. These days, modern cutting equipment relies on automation technology that follows precise measurements down to the millimeter. This means fewer costly errors and consistently good quality output across all production runs without fail.

This level of precision is crucial for advertising materials where even a slight misalignment or uneven cut can make the difference between a professional and subpar product.

Clean Edges and Quality Finishes

Modern cutting machines are designed to handle a variety of materials, from paper to vinyl, with clean and sharp cuts. This ensures that the final product has smooth edges and a polished look, essential for high-end advertising materials that make a lasting impression.

Increased Efficiency and Productivity

High-Speed Cutting for Larger Volumes

Advertising Printings Cutting Machines significantly speed up the cutting process compared to manual methods. With faster cutting speeds and the ability to work on multiple projects simultaneously, these machines allow businesses to produce large volumes of advertising materials in less time.

Whether itâs cutting dozens of flyers or large-format signage, a cutting machine can handle high-volume tasks efficiently, enabling businesses to meet tight deadlines and increase overall productivity.

Reduced Labor Costs

When these machines run on their own, companies don't need so many people doing the cutting by hand anymore. Less manual work means money saved on wages, sure, but it also gives employees something better to do than just standing there with shears. They can actually get involved in things like product design or checking if what comes out meets standards. And let's face it, when mistakes happen less often, nobody has to spend hours fixing them later. That saves both clock time and company cash in the long run.

Versatility in Material Handling

Wide Range of Compatible Materials

The Advertising Printings Cutting Machines come with pretty good versatility when it comes to handling all sorts of materials that are commonly used for ads. They work well with things like regular paper, thick cardboard, even those stiff foam boards, plus various plastics, vinyl sheets, and certain fabrics too. What makes these machines stand out is how they maintain decent quality across such diverse materials. For small business owners looking to expand what they can offer clients, this kind of flexibility opens up new possibilities. Instead of being limited to just one or two products, shops can now produce posters for events, large banners for storefronts, special packaging solutions, and eye-catching display items that really grab attention at trade shows or retail locations.

Ability to Cut Complex Shapes

When it comes to advertising, creative flair matters a lot, and being able to slice out complex shapes and designs makes all the difference. These days most cutting machines have fancy tech built right in, think lasers or those spinning rotary blades, which means they can make super accurate cuts even on tricky materials. For companies looking to stand out from the crowd, this kind of precision really pays off. Think about it: when a business wants to produce their own logoed stuff or eye catching promotional items with weird shapes, having access to these machines just makes sense. It saves time and money while still getting that professional finish clients expect.

Cost Efficiency and Reduced Waste

Minimizing Material Waste

When it comes to making those really clean cuts, Advertising Printings Cutting Machines do a great job at keeping waste to a minimum. Old school cutting techniques tend to leave behind quite a bit of scrap material, particularly noticeable when dealing with big sheets like vinyl or fabric. These modern machines maximize what gets used because they cut so precisely that there's hardly any leftover bits. For businesses, this means spending less cash on new materials while also being better for the planet since less goes into landfills.

Long-Term Cost Savings

The upfront cost for a cutting machine can definitely put a dent in the budget, but most businesses find it pays off over time. When looking at the bigger picture, these machines cut down on labor expenses, reduce material waste, and boost output across the board. That means better returns for the money spent. What's more, today's cutting equipment tends to last longer between breakdowns. Manufacturers report needing fewer repairs and replacements compared to older models, which adds another layer of savings that keeps growing month after month.

Conclusion â Why Invest in Advertising Printings Cutting Machines?

The Advertising Printings Cutting Machines bring real benefits to print shops, particularly ones working on ads and promotional stuff. These cutting tools give much better precision when trimming materials, which means less wasted stock going into the bin. They also speed things up quite a bit while allowing for all sorts of different jobs. Shops using these machines can crank out quality banners, posters, and other marketing materials at a quicker pace without breaking the bank. The time saved translates directly into higher profits for most businesses in this competitive field.

Investing in a cutting machine is an investment in the future of a business, enabling it to remain competitive in a fast-paced industry and meet the ever-growing demands of the advertising market.

FAQ

What materials can a printings cutting machine handle?

A printings cutting machine can handle a variety of materials, including paper, cardboard, vinyl, foam board, plastic, and fabric.

How does a cutting machine improve efficiency?

Cutting machines operate at high speeds, allowing businesses to produce large quantities of advertising materials quickly, reducing production time and increasing overall efficiency.

Can a cutting machine handle complex shapes?

Yes, many cutting machines are equipped with advanced technology that allows them to cut intricate shapes and designs, making them ideal for customized advertising materials.

What are the cost benefits of using a printings cutting machine?

Using a cutting machine reduces labor costs, minimizes material waste, and boosts production capacity, ultimately leading to long-term cost savings for the business.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES