Revolutionizing Factory Production with Advanced Mat Cutting Technology

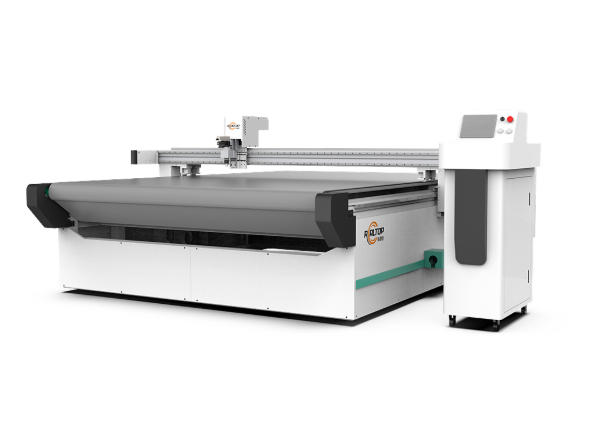

The manufacturing landscape is experiencing a significant transformation with the integration of carpet mat cutting machines into factory operations. These sophisticated pieces of equipment are reshaping how facilities approach mat production, offering unprecedented levels of precision, efficiency, and versatility. As industries continue to evolve, the role of automated cutting solutions becomes increasingly central to maintaining competitive advantage and meeting modern market demands.

Factory owners and production managers are discovering that carpet mat cutting machines represent more than just an equipment upgrade – they're a strategic investment that impacts every aspect of the manufacturing process. From reducing material waste to accelerating production timelines, these machines are proving to be game-changers in the industrial setting.

Operational Excellence and Cost Management

Enhanced Production Speed and Efficiency

Carpet mat cutting machines dramatically increase production capacity by automating what was traditionally a labor-intensive process. A single machine can typically perform the work of several manual cutting stations, operating continuously with minimal downtime. This heightened efficiency translates directly to improved output rates and shorter production cycles.

The precision and speed of these machines allow factories to handle larger order volumes without compromising quality. Production managers report that carpet mat cutting machines can process hundreds of units per hour, maintaining consistent quality throughout extended operation periods.

Significant Cost Reduction Opportunities

The implementation of carpet mat cutting machines leads to substantial cost savings across multiple areas. Labor costs decrease as fewer operators are needed to maintain production levels. Material waste is minimized through optimized cutting patterns and reduced human error, resulting in better utilization of raw materials.

Maintenance costs also tend to be lower compared to traditional cutting methods, as these machines are built for durability and require less frequent repairs. The initial investment in carpet mat cutting machines typically shows returns within the first year through these combined savings.

Quality Enhancement and Product Consistency

Precision Cutting and Pattern Accuracy

Modern carpet mat cutting machines utilize advanced computer-controlled systems to ensure exact measurements and clean cuts every time. This level of precision is impossible to achieve consistently with manual cutting methods. The machines can maintain accuracy down to fractions of a millimeter, ensuring that each product meets exact specifications.

Pattern replication becomes effortless as these machines can store hundreds of cutting templates in their memory. This capability enables factories to quickly switch between different designs while maintaining perfect consistency across production runs.

Material Optimization and Waste Reduction

Smart nesting algorithms in carpet mat cutting machines automatically calculate the most efficient way to lay out patterns on the material. This optimization reduces waste significantly, sometimes by as much as 30% compared to manual cutting methods. The machines can also handle various material thicknesses and types, adapting cutting parameters automatically to ensure optimal results.

Environmental benefits accompany these efficiency gains, as reduced waste means less material ends up in landfills. This aspect is increasingly important as consumers and businesses focus more on sustainability in manufacturing.

Workplace Safety and Employee Satisfaction

Improved Safety Standards

Carpet mat cutting machines incorporate numerous safety features that protect operators from potential injuries. Automated cutting processes eliminate the risks associated with manual cutting tools, such as blade injuries or repetitive strain issues. Safety sensors and emergency stop functions ensure immediate machine shutdown if any irregularities are detected.

The reduction in physical strain on workers leads to fewer workplace injuries and lower insurance costs for factories. Employees can focus on machine operation and quality control rather than performing potentially dangerous cutting tasks.

Enhanced Work Environment

The introduction of carpet mat cutting machines often leads to improved working conditions. Noise levels are typically lower than traditional cutting methods, and the automated nature of the work reduces physical strain on employees. Workers can be trained to operate these machines efficiently, opening up opportunities for skill development and career advancement.

Job satisfaction tends to increase as employees transition from repetitive manual labor to more skilled machine operation roles. This evolution in job responsibilities often results in higher employee retention rates and improved workplace morale.

Production Flexibility and Market Responsiveness

Rapid Design Implementation

Carpet mat cutting machines excel at quickly implementing new designs and pattern changes. Digital pattern input means that new designs can be programmed and put into production within minutes, allowing factories to respond rapidly to changing market demands or custom orders.

This flexibility enables manufacturers to maintain smaller inventories while offering a wider range of products. The ability to switch between different patterns without tooling changes represents a significant advantage in today's fast-paced market.

Customization Capabilities

Modern carpet mat cutting machines offer extensive customization options that were previously impractical or impossible with manual methods. Factories can easily produce custom sizes, shapes, and patterns to meet specific customer requirements. This capability opens new market opportunities and allows manufacturers to serve niche markets effectively.

The precision and repeatability of these machines make it feasible to offer customized products at scale, maintaining efficiency even with smaller batch sizes.

Frequently Asked Questions

How long does it take to train operators on carpet mat cutting machines?

Operator training typically takes between one to two weeks for basic operation, with additional time needed for advanced features. Most manufacturers provide comprehensive training programs and ongoing support to ensure optimal machine utilization.

What is the average return on investment period for carpet mat cutting machines?

While specific ROI periods vary depending on production volume and utilization, most factories report achieving full return on investment within 12-18 months through combined savings in labor, materials, and increased production capacity.

Are carpet mat cutting machines suitable for small-scale operations?

Yes, many manufacturers offer different sizes and capacities of carpet mat cutting machines to suit various production scales. Smaller operations can benefit from entry-level models that provide the same precision and efficiency benefits while requiring less floor space and initial investment.

How do carpet mat cutting machines handle different material types?

Modern carpet mat cutting machines are designed to work with a wide range of materials, including various carpet types, rubber, vinyl, and composite materials. They feature adjustable cutting parameters and tool options to optimize performance for different material properties.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES