No. 796-4, Dujiamiao village, Shizhong District, Jinan City, Shandong Province, China

+86-18764420158

[email protected]

No. 796-4, Dujiamiao village, Shizhong District, Jinan City, Shandong Province, China

+86-18764420158

[email protected]

Paired with an air flotation table and a cloth spreading machine, it can extend the feeding length.

Advantages in Cutting Textile Fabrics

1 . Significantly Enhanced Cutting Efficiency

✳Cutting speeds reach 12m/MIN, boosting productivity to 5–6 times that of manual cutting.

✳Supports multi-layer cutting (up to 70mm after adsorption), drastically reducing repetitive operations.

| Cutting length | 2000mm | 3000mm | |

| Cutting width | 1700mm | 1900mm | 2300mm |

| Max operating speed | 80m/MIN | ||

| Average cutting speed | 12m/MIN | ||

| Cutting thickness | 70mm | ||

| Voltage | 380V/50Hz | ||

| MAx Power | 26KW | ||

| Air flow volume | 160L/min | ||

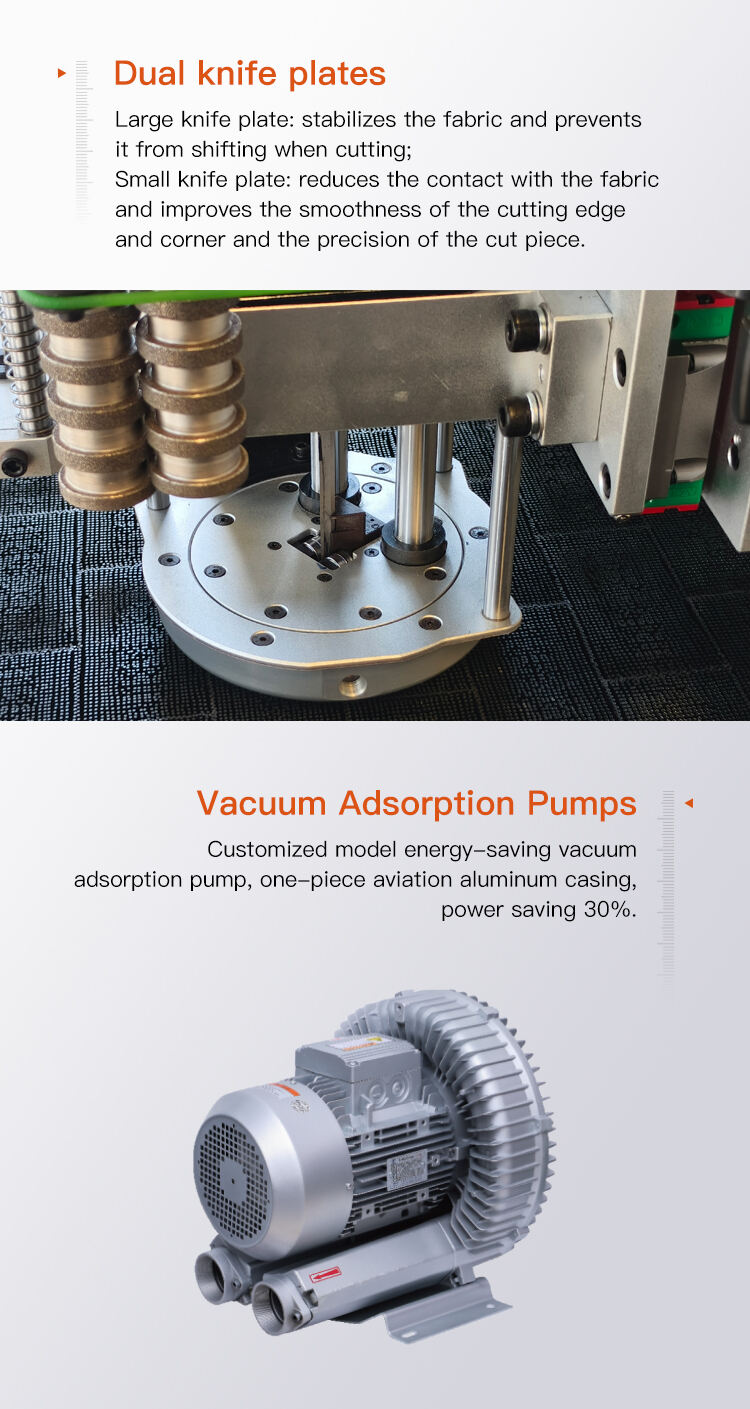

| Blade grinding method | Double rotary sharpenner | ||

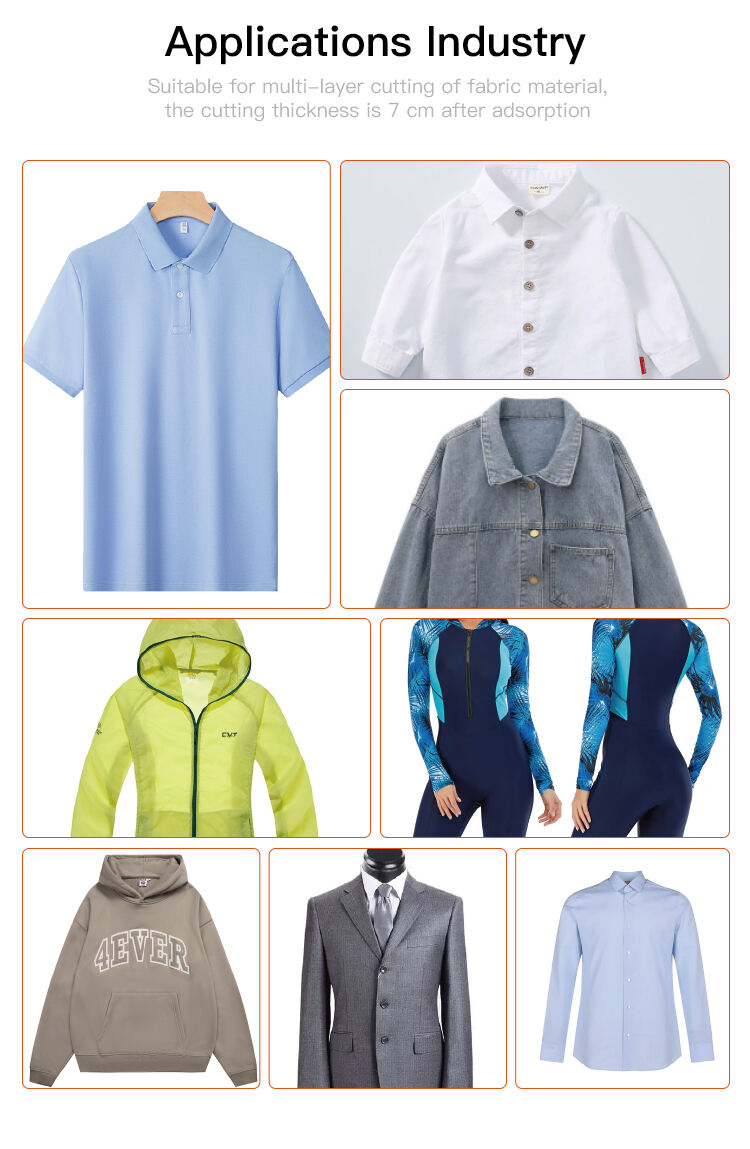

Typical Industry Applications:

Apparel Manufacturing: Efficiently cuts suits, knitwear, lace, and complex fabrics; supports pattern-matching layouts to enhance premium garment quality.

Home Textiles: Multi-layer cutting for sofa fabrics, curtains, and rugs; strong vacuum adsorption prevents material shifting.