Повышение производительности с помощью автоматических упаковочных резальных машин

Сокращение простоев в производстве благодаря автоматизации

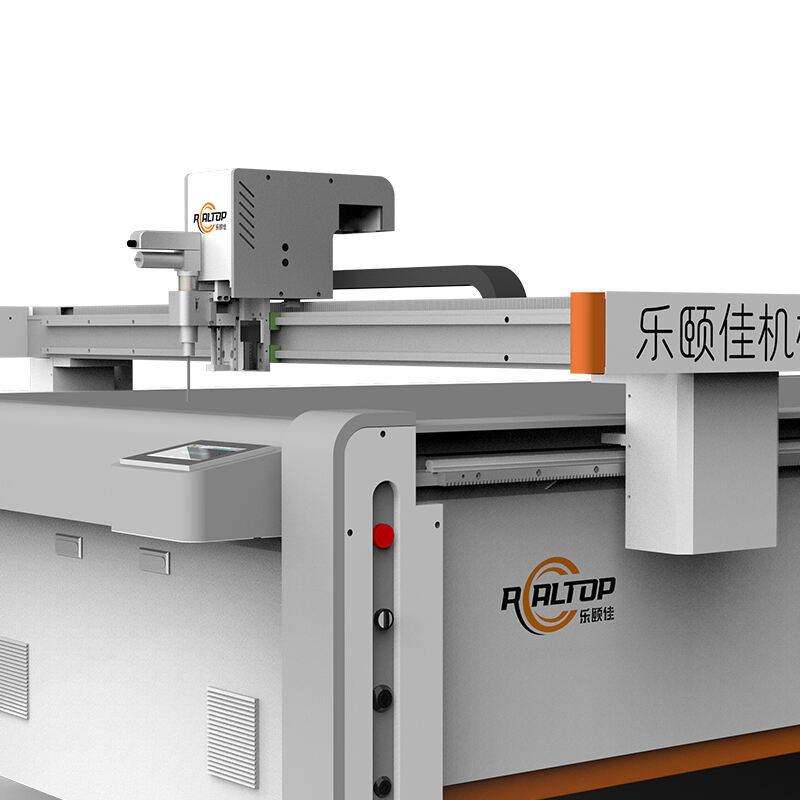

Предприятие, чья работа требует резки коробок определенной формы, знает, насколько важно иметь быстрые и точные машины для резки упаковки, так как чем быстрее эти производственные процессы, тем меньше задержек в производстве. И с помощью автоматизированного решения, такого как этот инструмент, производители могут работать непрерывно и избегать простоев, связанных с ручным управлением. Этот переход от ручных к электронным системам позволяет машинам работать без остановки, в отличие от ожидания, пока оператор нажмет кнопку СТАРТ, которая выключает машину спустя всего пять секунд. Кроме того, с использованием датчиков и обработки данных в реальном времени они могут легко адаптироваться к изменениям спроса на ходу. Эта гибкость повышает производительность, так как системы могут мгновенно перенастраиваться для учета изменений, избегая дорогих простоев и обеспечивая непрерывность производственной линии.

Обработка высоких объемов запросов без компромиссов

Машины спроектированы для эффективного производства больших объемов продукции с более высоким уровнем качества. Это обеспечивает постоянное качество выходной продукции даже при максимальных требованиях пропускной способности. Эти машины не только способны обрабатывать массовые заказы, но и могут одновременно обрабатывать различные материалы для удовлетворения конкретных потребностей клиентов. Эта гибкость критически важна в современной конкурентной деловой среде, где подвижность и настройка под клиента являются наиболее востребованными ценностями. Кроме того, с использованием автоматических решений компании могут лучше справляться с пиковыми нагрузками, масштабируя производство и избегая задержек, что гарантирует удовлетворенность клиентской базы. Автоматические упаковочные резальные машины являются ключевым препятствием для развития ручных машин и незаменимы для производства продукции высокого качества при текущем давлении.

Точная резка и постоянное качество

Постоянство материала на протяжении производственных циклов

Компьютеризированный упаковочный резальный станок имеет огромное преимущество в обеспечении точности реза и уровня материала на протяжении всего производственного цикла. Эта точность важна для поддержания последовательности бренда и гарантирует, что каждая упаковка будет точно одинакового размера и формы. При использовании в сочетании с сложными алгоритмами стабильность также способствует-consistency грануляции, таким образом, тройное отклонение между различными производственными циклами уменьшается. Эти операции по резке, как показали исследования, могут улучшить показатели качества продукции на 30%. Они также повышают удовлетворенность потребителей, так как покупатель может ожидать одинакового качества каждый раз, когда он покупает продукт.

Сокращение человеческого фактора с помощью передовых технологий

Применение высоких технологий на автоматизированных упаковочных резательных машинах решает проблему устранения человеческих ошибок во время резки. Это оборудование использует ИИ (искусственный интеллект) и адаптивное обучение для выявления заранее одной или нескольких потенциальных проблем, что позволяет своевременно принимать корректирующие меры для снижения вероятности дефектов. Производители должны быть хорошими хранителями материалов, и LaserLib является инструментом для тех, кто хочет максимально использовать материалы, а не тратить их впустую. Используя такие технологические инновации, производители получают возможность придерживаться уровня качества платформы, сохраняя при этом большую эффективность.

Снижение операционных расходов и зависимости от рабочей силы

Снижение трудовых затрат через автоматизацию

Предприятия, стремящиеся сократить трудовые затраты и повысить эффективность, обнаружат, что автоматизация упаковки является эффективной ключевой стратегией. Предприятия могут освободить человеческие ресурсы от повторяющихся операций по сборке и упаковке для более конструктивных и стратегических задач, таких как расширение и повышение производительности. Торговые автоматы обеспечивают отличную окупаемость инвестиций (ROI) за счет снижения заработной платы и увеличения выхода продукции. А отчет промышленных экономистов показывает, что компании, внедряющие автоматизацию, могут сократить трудовые затраты на 50% в течение пяти лет. Мы упускаем из виду то, что эта цифра не только демонстрирует масштаб возможной экономии, но и показывает феноменальный эффект, который автоматизация может оказать на операции.

Сокращение отходов материалов для экономии затрат

Резаки являются автоматизированными машинами, ключевыми для оптимизации материалов, что приводит к точным резам, способным минимизировать обрезки и отходы. Специфическая технология резки, которая может эффективно использовать материал, предлагает прямой способ экономии затрат для производителей. Бренды могут оптимизировать прибыль, осуществляя закупку материалов и производственные планы на основе анализа отходов. Эмпирические исследования показывают, что компании с меньшим количеством отходов благодаря автоматизации улучшают свою прибыльность в среднем на 15%. Этот успех доказывает, что автоматизация не только помогает положительно повлиять на устойчивость, но также оказывает прямое и немедленное воздействие на финансовый результат, и является необходимостью в современных операциях по упаковке.

Для получения более подробной информации об автоматизированных системах упаковки ознакомьтесь с нашим ассортиментом продукции, разработанной с использованием технологии точной резки.

Гибкость в обработке и применении материалов

Адаптация к картону, пластикам и пенопласту

Автоматизированные упаковочные режущие машины для резки картонных и пластиковых листов подходят для множества продуктов, которым требуется коробка нестандартного размера, изготовленная из картона или гофрокартона. Два вида насосных головок позволяют некоторым отраслям быстро менять материал. Сокращение времени замены, чтобы избежать холостого хода и удалить пробный материал. Продвинутые лезвия и механика резки, используемые в этих системах, обеспечивают точное и эффективное выполнение сложных резов, при этом используется каждый дюйм доступного материала. Эта функция полезна не только для производственных линий, но и применима в нескольких областях различных отраслей, что делает их важными с точки зрения упаковки.

Специальные решения для уникальных упаковочных потребностей

Использование автоматических систем резки позволяет производителям создавать персонализированную упаковку, которая удовлетворяет потребности продукта. Благодаря инновационным конструкционным особенностям этих машин становятся возможными уникальные формы и размеры упаковки, что усиливает присутствие продукта на полке и его защиту во время транспортировки. Дизайнеры заводов могут сотрудничать с инженерами-механиками для разработки индивидуальных систем, которые решают специфические рыночные задачи и способствуют конкурентному преимуществу. Считается, что такая персонализированная маркетинговая стратегия хорошо вписывается в современные тенденции рынка, который стремится удовлетворять потребности и предпочтения покупателей через индивидуальный подход, тем самым сочетая практичность с эстетикой в решениях по упаковке.

Бесшовная интеграция в существующие рабочие процессы

Совместимость с современными производственными линиями

Машины для резки упаковочных материалов очень легко интегрируются с новейшими производственными линиями и вызывают минимальные перерывы в работе при запуске. Функция Plug-and-Play: самое значительное преимущество, способствующее бесшовному переходу при использовании этих машин. Опция установщика доступна для простой и быстрой установки и настройки данных машин с целью минимизации простоев, которые могут повлиять на производственные графики. Существует множество историй успеха, описывающих, как крупные фабрики повысили эффективность рабочих процессов благодаря использованию автоматических систем резки, что свидетельствует о том, что автоматическая машина для резки подходит для современных производственных процессов. Интегрируя эти передовые решения, предприятия могут повысить эффективность и улучшить процессы упаковки для экономически эффективной и рентабельной работы.

Масштабируемость для растущих производственных потребностей

По мере роста потребностей бизнеса, возможность расширяться без значительных добавлений инфраструктуры критически важна для производителей. Упаковочные режущие машины масштабируемы, что позволяет компаниям увеличивать производственные мощности в соответствии с возрастающим спросом. Благодаря модульному дизайну этого оборудования, производители могут постепенно модифицировать и обновлять свои системы, оставаясь конкурентоспособными на постоянно меняющемся рынке. По прогнозам большинства экспертов отрасли, масштабируемые решения должны сыграть ключевую роль в операционном росте в течение следующего десятилетия. Производители могут создать стандартизированный, последовательный внешний вид упаковки, чтобы соответствовать растущему спросу клиентов, при этом сохраняя высокое качество стандартов упаковки благодаря внедрению автоматизированных решений, готовых к будущим изменениям рынка.

Раздел часто задаваемых вопросов

Что такое автоматизированные упаковочные резальные машины?

Автоматизированные упаковочные резательные машины — это устройства, которые оптимизируют процессы резки в производстве, обеспечивая точность и эффективность за счёт автоматизации задач, традиционно выполняемых вручную.

Как эти машины помогают в снижении задержек производства?

Они значительно сокращают задержки производства, позволяя непрерывную работу без ручного вмешательства, при этом поддерживаемые датчиками и анализом данных в реальном времени для быстрой адаптации к изменениям спроса.

Могут ли эти машины обрабатывать разные материалы?

Да, автоматизированные упаковочные резательные машины универсальны и могут обрабатывать различные материалы, такие как картон, пластик и пенопласт, удовлетворяя потребности множества отраслей и способствуя повышению производительности.

Как автоматизированные машины снижают зависимость от рабочей силы?

Автоматизируя процесс упаковки, эти машины снижают затраты на рабочую силу, уменьшают ручное вмешательство и позволяют человеческим ресурсам сосредоточиться на более стратегически важных задачах внутри компании.

Адаптируются ли эти машины под растущие потребности бизнеса?

Да, модульный дизайн этих машин позволяет предприятиям эффективно масштабировать операции, удовлетворяя растущие производственные потребности без значительных инвестиций в инфраструктуру.

Содержание

-

Повышение производительности с помощью автоматических упаковочных резальных машин

- Сокращение простоев в производстве благодаря автоматизации

- Обработка высоких объемов запросов без компромиссов

- Точная резка и постоянное качество

- Постоянство материала на протяжении производственных циклов

- Сокращение человеческого фактора с помощью передовых технологий

- Снижение операционных расходов и зависимости от рабочей силы

- Снижение трудовых затрат через автоматизацию

- Сокращение отходов материалов для экономии затрат

- Гибкость в обработке и применении материалов

- Адаптация к картону, пластикам и пенопласту

- Специальные решения для уникальных упаковочных потребностей

- Бесшовная интеграция в существующие рабочие процессы

- Совместимость с современными производственными линиями

- Масштабируемость для растущих производственных потребностей

- Раздел часто задаваемых вопросов

- Что такое автоматизированные упаковочные резальные машины?

- Как эти машины помогают в снижении задержек производства?

- Могут ли эти машины обрабатывать разные материалы?

- Как автоматизированные машины снижают зависимость от рабочей силы?

- Адаптируются ли эти машины под растущие потребности бизнеса?

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES