The manufacturing landscape is experiencing a revolutionary shift as industries pivot toward sustainable and innovative materials. Traditional leather cutters face unprecedented challenges as synthetic alternatives flood the market, demanding sophisticated adaptations in cutting technology. Modern production facilities must evolve their equipment capabilities to handle diverse material compositions while maintaining precision and efficiency standards.

Synthetic materials present unique properties that differ significantly from traditional leather, requiring manufacturers to reassess their cutting strategies. These advanced materials often exhibit varying densities, elasticity coefficients, and thermal responses that challenge conventional cutting methodologies. Understanding these material characteristics becomes crucial for optimizing production workflows and achieving consistent quality outcomes.

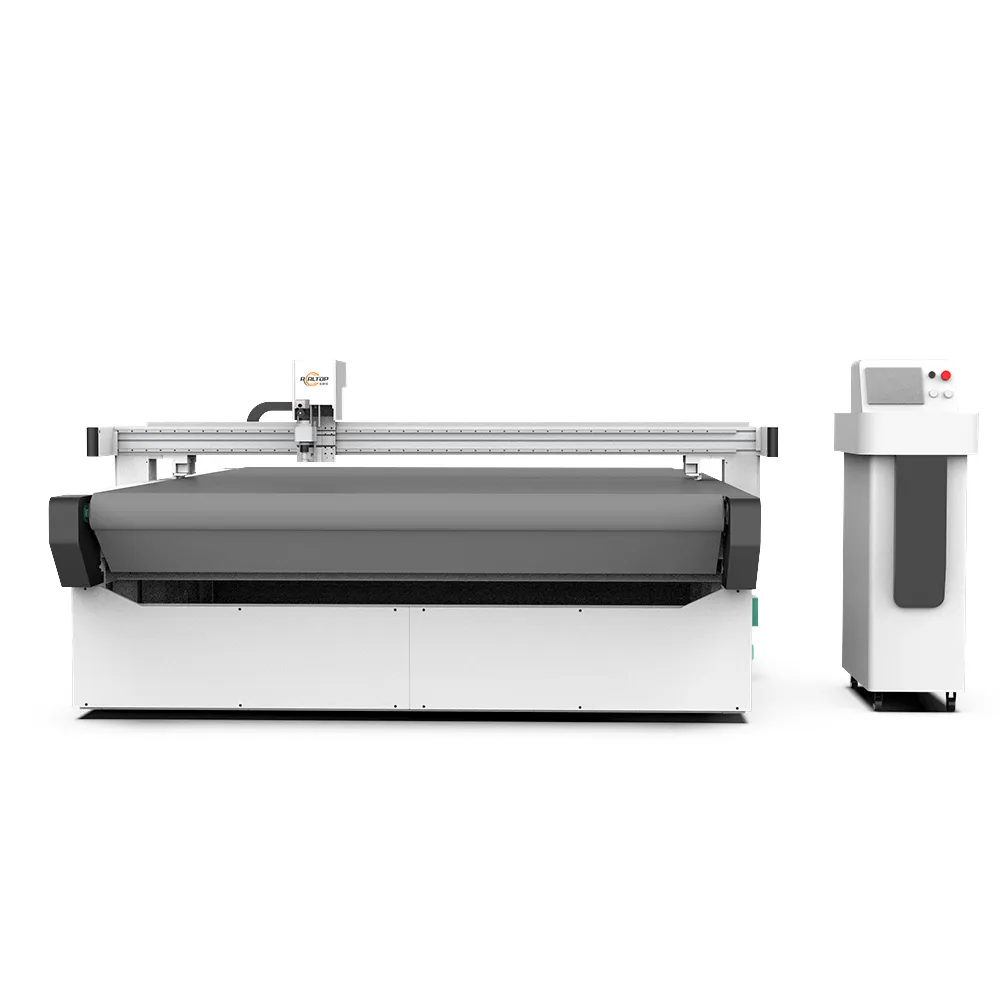

The integration of computer numerical control technology has transformed how manufacturers approach material processing challenges. Advanced cutting systems now incorporate intelligent sensors and adaptive algorithms that automatically adjust parameters based on material feedback. This technological evolution enables seamless transitions between different synthetic materials without compromising precision or production speed.

Understanding Synthetic Material Properties

Chemical Composition Variations

Synthetic materials encompass a broad spectrum of chemical compositions, each presenting distinct cutting challenges for industrial applications. Polyurethane-based synthetics exhibit different molecular structures compared to polyvinyl chloride alternatives, directly impacting cutting blade selection and operational parameters. These compositional differences require specialized knowledge to optimize cutting performance and minimize material waste.

The molecular density of synthetic materials often exceeds traditional leather, creating increased resistance during cutting operations. This elevated density necessitates enhanced cutting force application while maintaining precise edge quality throughout the production process. Understanding these chemical properties enables manufacturers to select appropriate cutting technologies that deliver consistent results across diverse material types.

Thermal Response Characteristics

Heat generation during cutting operations affects synthetic materials differently than natural leather, often causing edge melting or distortion issues. Advanced leather cutters incorporate cooling systems and temperature monitoring to prevent thermal damage during high-speed processing. These thermal management features ensure clean edge formation while preserving material integrity throughout the cutting cycle.

Temperature sensitivity varies significantly among different synthetic formulations, requiring adaptive cooling strategies for optimal results. Some materials require immediate cooling post-cutting to prevent edge deformation, while others benefit from controlled heating to achieve specific edge characteristics. This thermal complexity demands sophisticated control systems capable of real-time parameter adjustments based on material feedback.

Advanced Cutting Technologies for Synthetic Materials

Precision Blade Technologies

Modern cutting blade technology has evolved to address the unique challenges presented by synthetic material processing. Ultra-sharp ceramic blades offer superior edge retention when cutting abrasive synthetic materials, extending operational life while maintaining consistent cutting quality. These advanced blade materials resist wear patterns that commonly affect traditional steel blades during synthetic material processing.

Specialized blade geometries optimize cutting performance for specific synthetic material types, incorporating features like serrated edges or oscillating motion patterns. These geometric innovations reduce cutting force requirements while improving edge quality and processing speed. The selection of appropriate blade technology directly impacts production efficiency and final product quality standards.

Computer-Controlled Precision Systems

Computer numerical control integration enables unprecedented precision in synthetic material cutting applications, offering repeatability levels essential for high-volume production environments. These systems incorporate real-time material recognition capabilities that automatically adjust cutting parameters based on detected material properties. This intelligent adaptation eliminates manual parameter adjustment requirements while ensuring consistent quality outcomes.

Advanced motion control algorithms optimize cutting path efficiency while minimizing material stress concentrations that could compromise edge integrity. These systems calculate optimal approach angles and cutting speeds for each material type, reducing processing time while maintaining superior quality standards. The integration of artificial intelligence components enables continuous learning and optimization based on historical performance data.

Material Testing and Quality Assurance

Pre-Cutting Material Analysis

Comprehensive material analysis protocols ensure optimal cutting parameter selection before production begins, minimizing waste and maximizing efficiency. Advanced testing equipment evaluates material density, elasticity, and thermal properties to establish baseline cutting parameters. This analytical approach reduces trial-and-error periods while ensuring first-pass quality achievements.

Non-destructive testing methods enable rapid material characterization without compromising production material supplies. These testing protocols identify potential cutting challenges before they impact production schedules or quality outcomes. Implementation of standardized testing procedures ensures consistent parameter selection across different production batches and material lots.

Edge Quality Assessment

Post-cutting quality assessment protocols verify edge integrity and dimensional accuracy throughout production runs, maintaining consistent quality standards. Advanced imaging systems capture microscopic edge details that reveal cutting performance characteristics and potential optimization opportunities. These assessment tools enable continuous process improvement while ensuring final product specifications are consistently achieved.

Statistical process control methodologies track cutting performance trends over time, identifying degradation patterns before they impact product quality. This proactive approach enables preventive maintenance scheduling and parameter optimization based on actual performance data. Regular quality assessment ensures cutting systems maintain peak performance throughout extended production campaigns.

Operational Efficiency Optimization

Workflow Integration Strategies

Seamless workflow integration ensures synthetic material cutting operations complement existing production processes without creating bottlenecks or efficiency losses. Advanced scheduling algorithms optimize cutting sequence planning based on material types and production priorities. These integration strategies maximize equipment utilization while maintaining production flexibility for changing order requirements.

Automated material handling systems reduce manual intervention requirements while ensuring consistent material positioning for optimal cutting results. These systems incorporate vision guidance technology that precisely positions materials regardless of dimensional variations or surface characteristics. Implementation of automated workflows significantly reduces labor requirements while improving overall production consistency.

Maintenance and Calibration Protocols

Preventive maintenance protocols ensure cutting systems maintain peak performance when processing challenging synthetic materials that accelerate component wear. Regular calibration procedures verify system accuracy and precision levels essential for meeting strict quality requirements. These maintenance strategies extend equipment life while minimizing unexpected downtime events that disrupt production schedules.

Predictive maintenance technologies monitor cutting system performance parameters to identify potential issues before they cause quality problems or equipment failures. These monitoring systems track blade wear patterns, system vibrations, and thermal conditions that indicate maintenance requirements. Early intervention based on predictive data significantly reduces maintenance costs while maximizing equipment availability.

Cost-Benefit Analysis and ROI Considerations

Investment Justification Metrics

Comprehensive cost analysis demonstrates the financial benefits of upgrading cutting systems for synthetic material processing capabilities. Initial investment costs must be evaluated against long-term savings from reduced material waste, improved processing speeds, and enhanced product quality. These financial metrics provide clear justification for technology upgrades that enable synthetic material processing capabilities.

Return on investment calculations should include factors such as reduced labor requirements, decreased material waste, and improved production throughput rates. Advanced cutting systems often pay for themselves within months through efficiency gains and quality improvements. Detailed financial analysis ensures decision-makers understand the complete economic impact of cutting system upgrades.

Long-Term Operational Savings

Extended equipment life and reduced maintenance requirements contribute significantly to long-term operational cost reductions when processing synthetic materials. Advanced cutting technologies often require less frequent blade replacement and system maintenance compared to conventional alternatives. These operational savings compound over time, creating substantial cost advantages for facilities processing diverse material types.

Quality improvements resulting from advanced cutting technologies reduce rework costs and customer returns that impact profitability. Consistent edge quality and dimensional accuracy eliminate quality-related production delays and material waste. These quality benefits translate directly into improved profit margins and customer satisfaction levels.

FAQ

How do synthetic materials differ from traditional leather in cutting requirements

Synthetic materials typically exhibit higher density and different thermal properties compared to traditional leather, requiring adjusted cutting parameters and specialized blade technologies. These materials often generate more heat during cutting and may require enhanced cooling systems to prevent edge distortion. The chemical composition of synthetics also affects blade wear patterns, necessitating more frequent blade maintenance or specialized blade materials for optimal performance.

What are the key features to look for in cutting systems for synthetic materials

Essential features include adaptive parameter control, advanced cooling systems, precision blade positioning, and real-time material recognition capabilities. Computer numerical control integration enables automatic parameter adjustment based on material type, while thermal management systems prevent heat-related edge damage. Additionally, robust construction and enhanced cutting force capabilities ensure reliable performance when processing dense synthetic materials.

How can manufacturers optimize their cutting processes for multiple material types

Implementation of intelligent cutting systems with material recognition capabilities enables automatic parameter optimization for different material types without manual intervention. Establishing comprehensive material databases with pre-defined cutting parameters streamlines production transitions between material types. Regular system calibration and maintenance ensure consistent performance across diverse material applications while minimizing setup time and material waste.

What maintenance considerations are unique to synthetic material cutting operations

Synthetic materials often cause accelerated blade wear due to their abrasive properties and higher cutting forces required for processing. Enhanced cleaning protocols may be necessary to remove synthetic material residues that can accumulate on cutting components. Additionally, cooling system maintenance becomes more critical when processing synthetics due to increased heat generation during cutting operations, requiring regular coolant replacement and system cleaning procedures.

Table of Contents

- Understanding Synthetic Material Properties

- Advanced Cutting Technologies for Synthetic Materials

- Material Testing and Quality Assurance

- Operational Efficiency Optimization

- Cost-Benefit Analysis and ROI Considerations

-

FAQ

- How do synthetic materials differ from traditional leather in cutting requirements

- What are the key features to look for in cutting systems for synthetic materials

- How can manufacturers optimize their cutting processes for multiple material types

- What maintenance considerations are unique to synthetic material cutting operations

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES