The Evolution of Modern Carpet Mat Manufacturing Technology

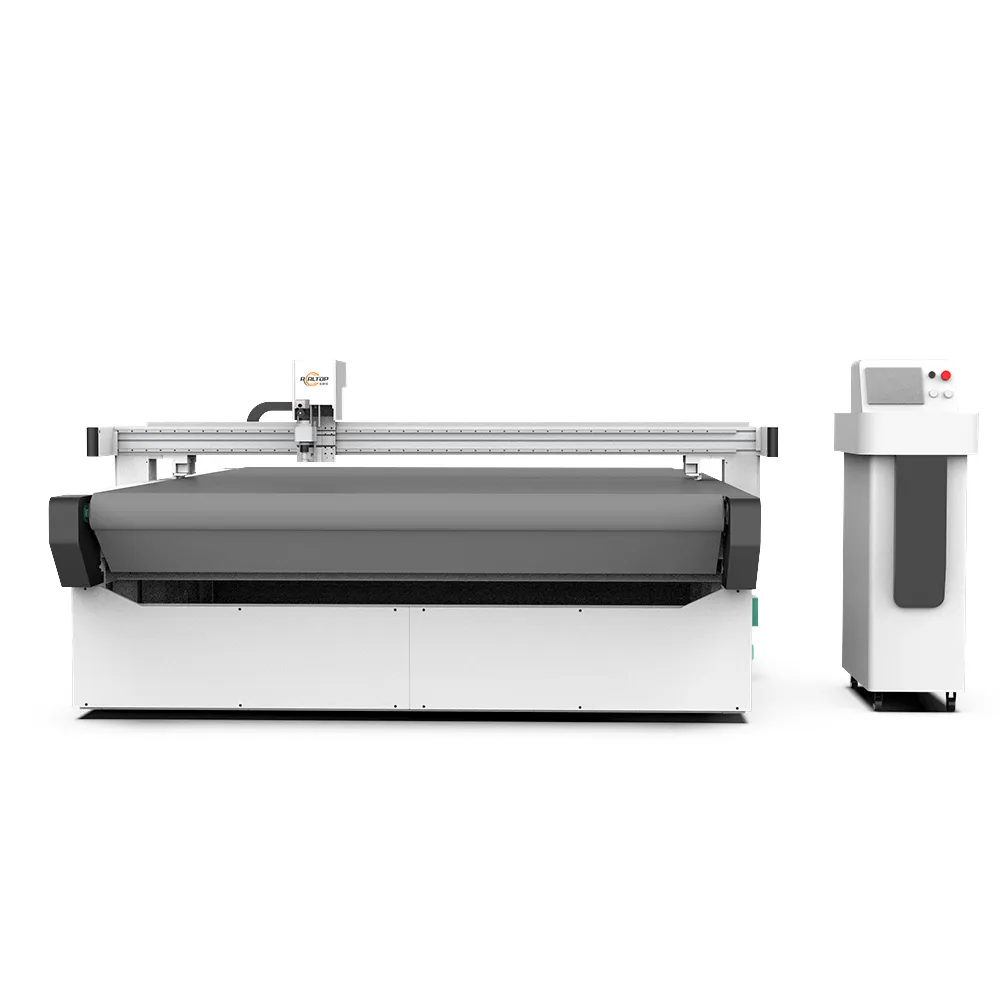

The landscape of carpet mat production has been revolutionized by the introduction of sophisticated carpet mat cutting machines. These advanced systems have transformed what was once a labor-intensive manual process into a streamlined, efficient operation that delivers precision and consistency. Today's manufacturing facilities rely heavily on these machines to meet growing market demands while maintaining exceptional quality standards.

Industrial Applications and Manufacturing Benefits

Automotive Industry Integration

The automotive sector represents one of the largest markets for carpet mat cutting machines. Vehicle manufacturers require precise, custom-fitted floor mats that meet strict quality specifications. These machines excel at producing perfectly sized mats with reinforced edges and precise cutouts for pedals and seat attachments. The ability to program exact measurements ensures consistent production runs that align perfectly with different vehicle models and trim levels.

Modern carpet mat cutting machines can process multiple material layers simultaneously, incorporating backing materials and edge binding in a single operation. This integration significantly reduces production time while ensuring durability in the final product. Automotive manufacturers particularly value the ability to quickly adapt cutting patterns for new vehicle models without extensive retooling.

Commercial Building Solutions

Commercial properties present unique challenges that carpet mat cutting machines are uniquely equipped to address. From hotel lobbies to corporate offices, these facilities require entrance mats and area rugs that combine functionality with aesthetic appeal. The precision cutting capabilities allow for intricate logo designs and custom shapes that enhance branding while maintaining durability.

The machines excel at producing large-format mats with consistent edge finishing, crucial for high-traffic areas. Building managers appreciate the ability to order exact-fit replacements that maintain a professional appearance while meeting safety requirements. The technology enables quick turnaround times for custom orders, essential for property renovations and maintenance schedules.

Specialized Industry Applications

Marine and Aviation Sectors

The marine and aviation industries demand specialized flooring solutions that carpet mat cutting machines deliver with remarkable precision. These sectors require materials that resist water damage, provide secure footing, and meet strict safety regulations. Advanced cutting systems can process specialized marine-grade carpeting and anti-slip materials while maintaining precise dimensions for complex cabin layouts.

Yacht builders and aircraft manufacturers rely on these machines to create custom-fitted pieces that conform to curved surfaces and irregular spaces. The technology's ability to handle multiple material types proves invaluable when creating layered solutions that combine water resistance with luxury aesthetics.

Hospitality and Event Management

Hotels, convention centers, and event venues benefit significantly from carpet mat cutting machines through their ability to produce custom floor coverings for different occasions. These facilities often require temporary installations that must be both attractive and durable. The machines enable rapid production of themed floor coverings, directional pathways, and branded entrance mats.

Event planners particularly value the quick turnaround capabilities when creating custom carpet installations for weddings, trade shows, and corporate events. The precision cutting ensures perfect fits around stages, seating areas, and display configurations, while maintaining consistent branding elements throughout the space.

Technology Integration and Future Developments

Digital Design Integration

Modern carpet mat cutting machines integrate seamlessly with digital design software, allowing for complex pattern creation and rapid prototyping. This integration enables manufacturers to visualize final products before cutting begins, reducing material waste and ensuring customer satisfaction. The ability to store and modify cutting patterns digitally streamlines the reordering process and maintains consistency across production runs.

Advanced systems now incorporate real-time monitoring and adjustment capabilities, ensuring optimal cutting performance even with varying material properties. This technological integration has opened new possibilities for customization while maintaining efficient production schedules.

Sustainable Manufacturing Practices

The precision of carpet mat cutting machines contributes significantly to sustainable manufacturing practices. By optimizing material usage and reducing waste, these systems help companies meet environmental goals while maintaining profitability. The machines' ability to nest patterns efficiently maximizes material utilization, particularly important when working with expensive or eco-friendly materials.

Manufacturers are increasingly incorporating recycled materials into their production processes, and carpet mat cutting machines prove essential in maintaining quality standards with these alternative materials. The technology's adaptability ensures consistent results regardless of material composition, supporting the industry's shift toward sustainability.

Frequently Asked Questions

How do carpet mat cutting machines enhance production efficiency?

Carpet mat cutting machines significantly improve production efficiency through automated processes, precise cutting capabilities, and reduced material waste. They can handle multiple layers simultaneously, incorporate various materials, and maintain consistent quality across large production runs. The digital integration allows for quick pattern changes and efficient material utilization.

What maintenance requirements do carpet mat cutting machines have?

Regular maintenance includes cleaning cutting surfaces, lubricating moving parts, and calibrating alignment systems. Professional servicing is recommended quarterly, with daily inspections of cutting tools and vacuum systems. Proper maintenance ensures optimal performance and extends the machine's operational lifespan.

Can carpet mat cutting machines handle custom designs and logos?

Yes, modern carpet mat cutting machines excel at producing custom designs and logos. They can interpret vector graphics and complex patterns, creating precise cuts for branded mats and decorative elements. The machines' digital controls ensure consistent reproduction of intricate designs across multiple production runs.

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES