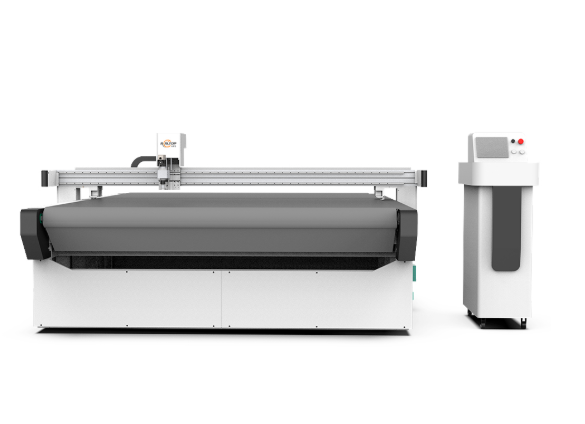

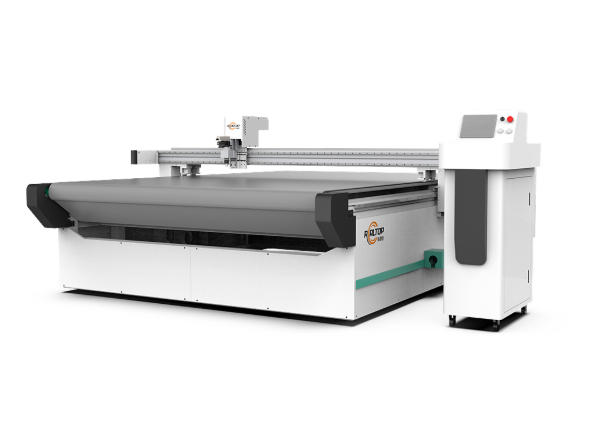

Carpet mats play an important role across many different sectors, bringing comfort, insulation and safety to homes as well as businesses. Making these mats demands careful attention to detail, efficient processes, and working knowledge of diverse materials ranging from synthetic fibers to natural wool blends. For those in the carpet and flooring business, carpet mat cutting machines have pretty much become essential equipment nowadays. These machines offer real benefits that make a difference in how fast things get done, the overall quality of the finished product, and ultimately what it costs to produce each batch. Manufacturers who invest in good cutting technology typically see improvements throughout their entire operation.

This article highlights the primary benefits of using Carpet Mat Cutting Machines, explaining how they improve the overall production process, reduce material waste, and ensure a high-quality final product.

Enhanced Precision and Quality

Accurate and Consistent Cuts

Carpet mat cutting machines really shine when it comes to making accurate cuts time after time. Back in the day, people would try slicing these mats with regular cutters or even scissors, but let's face it - those old ways just don't cut it anymore. What happens? Uneven edges all over the place, sometimes whole sections too big or too small. This messiness doesn't look good at all and means plenty of rejected products sitting around collecting dust instead of being sold.

A cutting machine, on the other hand, ensures that each mat is cut to the exact specifications. Whether youâre working with large sheets or intricate designs, Carpet Mat Cutting Machines guarantee clean, straight edges and uniform dimensions, which are critical for both functionality and appearance.

Reducing Material Waste

These machines make really accurate cuts, so they cut down on wasted materials too. Manual cutting or using old school equipment just invites mistakes, and we all know what happens when that occurs valuable stuff gets thrown away for nothing. With Carpet Mat Cutting Machines, everything runs smoother during the actual cutting phase. Raw materials actually get put to good use instead of ending up as scrap heap fodder most of the time. Just think about all those saved resources over months and years of operation.

For manufacturers working with expensive carpet materials, this reduction in waste leads to significant cost savings and supports more sustainable production practices.

Increased Speed and Productivity

Faster Cutting Processes

Carpet mat cutting machines cut through materials much quicker than doing it by hand. These industrial tools can slice through dozens of mats at once while workers struggle with just one or two at a time. For commercial operations that need hundreds of custom mats produced daily, this kind of machine saves hours every week. The increased productivity means shops can take on bigger orders without missing delivery dates. Plus, manufacturers get more product out the door each month, giving them an edge when competing against other suppliers in the marketplace.

Continuous Operation and Automation

Most modern cutting machines come equipped with automation systems that keep them running nonstop without much hands-on work from operators. These machines can slice through big stacks of carpet mats all day long, which means manufacturers get their products done faster than ever before while needing fewer workers standing by to monitor everything. The automation aspect is pretty amazing too because it cuts down on mistakes people might make when doing repetitive tasks manually. Fewer mistakes translate to less waste in the factory and customers end up getting consistently good quality mats instead of some batch being perfect and others full of flaws.

Versatility in Material Handling

Ability to Handle Various Carpet Types

Carpet mat cutting machines work really well across all sorts of materials. They handle everything from those short pile carpets right up to the taller ones, plus they cut through things like rubber and foam mats too. When working on heavy duty industrial mats versus something lighter like decorative floor coverings, operators just need to tweak a few settings on the machine. The adjustments let it cope with varying thickness levels and different surface textures without much hassle at all. This kind of adaptability makes these machines super valuable for production shops dealing with multiple product lines.

Cutting Custom Shapes and Designs

In many commercial and industrial spaces, carpet mats just don't come off the shelf ready to go. They need special cuts for odd corners, awkward doorways, or those weird shaped rooms nobody seems to plan properly. Modern cutting machines solve this problem by slicing through materials with computer precision. These machines handle everything from intricate company logos to unusual geometric designs, giving manufacturers the tools they need when clients ask for something different than standard stock items. The design freedom matters a lot too. Retail chains want their branding on every floor mat, while factories might need safety markers in specific locations. Without this kind of customization option, businesses would either settle for imperfect solutions or spend way more money getting things made elsewhere.

Cost Efficiency and Long-Term Savings

Reducing Labor Costs

The introduction of carpet mat cutting machines has made a real difference in cutting down on labor expenses through automation. When done manually, this kind of cutting demands workers with special skills and just takes forever to finish properly. With these machines in place, companies need far fewer staff members for the job, plus each production batch gets completed much quicker than before. The saved time means workers can focus on areas where their expertise matters most, like making sure products meet quality standards or getting them ready for shipment out the door.

Extended Machine Life and Durability

These machines are designed for long-term durability and reliability. Unlike manual methods, which can be subject to wear and tear, Carpet Mat Cutting Machines offer consistent performance over time with proper maintenance. The high durability of these machines means fewer breakdowns, reducing repair costs and downtime.

Improved Safety and Working Conditions

Reducing Manual Handling Risks

When workers cut carpet mats by hand, they often end up handling sharp tools all day long while doing the same motions over and over again. This kind of work doesn't just get tiring it actually puts people at real risk for getting hurt on the job. That's where carpet mat cutting machines come into play. These devices take care of most of the dangerous parts automatically. They have those protective covers around the blades, will turn themselves off if something goes wrong, and are designed so operators don't strain their bodies quite as much. The combination of these safety elements makes a huge difference in keeping workplaces accident free.

Conclusion â Why Invest in Carpet Mat Cutting Machines?

Getting a carpet mat cutting machine brings real advantages to production processes. These machines cut down on material waste significantly while producing consistently good quality products. The precision they offer means fewer mistakes during manufacturing runs. Plus, operations run much faster compared to manual methods. For businesses making custom carpet mats, this equipment translates into actual cost savings over time. Safety improvements are another plus point as workers aren't handling sharp tools as often. With consumer demand for personalized floor coverings rising steadily across commercial and residential markets alike, having reliable cutting technology gives manufacturers an important advantage when competing against rivals who still rely on older methods.

For businesses aiming to enhance production processes and product quality, adopting Carpet Mat Cutting Machines is a smart move that pays off in the long run.

FAQ

What types of carpets can be cut with a carpet mat cutting machine?

These machines can cut various carpet types, including low-pile, high-pile, rubber mats, foam mats, and custom materials designed for specific applications.

How do carpet mat cutting machines reduce material waste?

The machines provide accurate cuts, minimizing errors and ensuring better utilization of raw materials, thus reducing material waste.

Are these machines suitable for custom shapes and sizes?

Yes, Carpet Mat Cutting Machines can be programmed to cut custom shapes, sizes, and even intricate designs, making them ideal for bespoke orders.

How does a carpet mat cutting machine improve safety?

By automating the cutting process, these machines reduce the need for manual handling, minimizing the risk of operator injuries and creating a safer work environme

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES