As operações industriais de corte de juntas exigem precisão, confiabilidade e desempenho consistente para atender aos rigorosos padrões de fabricação. Quando as linhas de produção dependem de dimensões precisas das juntas para aplicações críticas de vedação, manter os equipamentos de corte em condições ideais torna-se fundamental para o sucesso operacional. Protocolos profissionais de manutenção garantem que as máquinas de corte ofereçam a precisão dimensional necessária para aplicações automotivas, aeroespaciais e industriais, nas quais a falha de componentes pode resultar em interrupções operacionais significativas e preocupações com segurança.

A complexidade dos sistemas de corte modernos requer estratégias de manutenção abrangentes que abordem componentes mecânicos, ferramentas de corte, sistemas de controle e fatores ambientais. Compreender a relação crítica entre manutenção preventiva e precisão de corte permite que os fabricantes estabeleçam protocolos que minimizem o tempo de inatividade, maximizando a vida útil do equipamento. Estas práticas de manutenção têm um impacto direto na qualidade do produto, na eficiência da produção e nos custos gerais de fabrico durante todo o ciclo de vida do equipamento.

Procedimentos Essenciais de Manutenção Diária

Inspecção do equipamento antes da operação

As inspeções diárias pré-operacionais formam a base de programas eficazes de manutenção de máquinas cortadoras de juntas. Esses controles sistemáticos identificam problemas potenciais antes que eles se transformem em reparos onerosos ou atrasos na produção. Os operadores devem examinar o estado da lâmina de corte, verificando sinais de desgaste, danos ou alinhamento incorreto que possam comprometer a precisão do corte. A inspeção visual dos trilhos guia, sistemas de alimentação de material e componentes pneumáticos garante a prontidão operacional ideal.

Os sistemas de lubrificação da máquina exigem verificação diária para confirmar os níveis adequados de óleo e a distribuição de lubrificante em todos os componentes móveis críticos. A lubrificação inadequada pode causar desgaste excessivo, aumento das temperaturas de operação e falha prematura de componentes. Os operadores também devem verificar se os sistemas de vácuo mantêm níveis de sucção apropriados para manipulação de materiais e remoção de resíduos, pois pressão de vácuo insuficiente pode afetar a qualidade do corte e a segurança no ambiente de trabalho.

Avaliação e Calibração de Ferramentas de Corte

O estado da ferramenta de corte influencia diretamente a precisão dimensional e a qualidade das bordas das juntas acabadas. Os protocolos diários de inspeção devem avaliar a nitidez da lâmina, a geometria da borda e a estabilidade da montagem. Ferramentas de corte desgastadas ou danificadas produzem bordas irregulares, variações dimensionais e maior desperdício de material. A calibração regular das ferramentas garante que os parâmetros de corte permaneçam dentro das tolerâncias especificadas para diferentes materiais e espessuras de juntas.

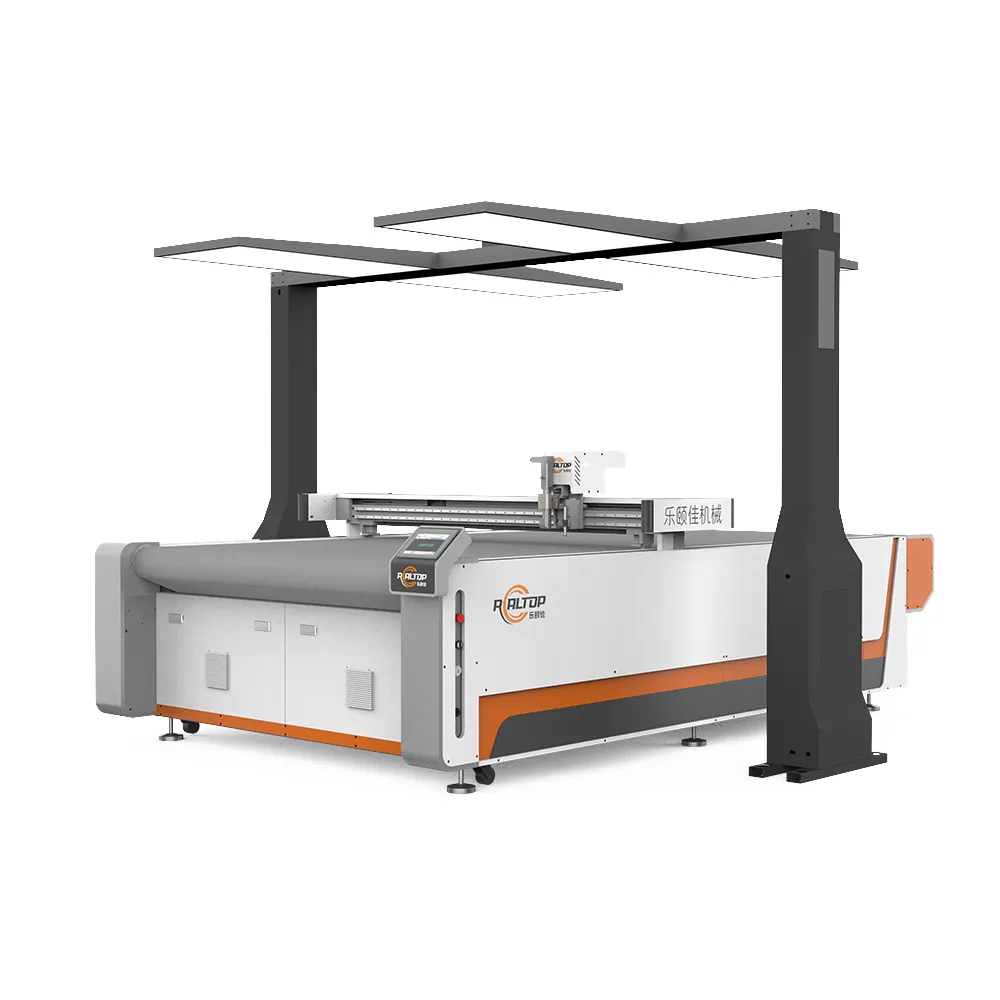

Equipes profissionais de manutenção estabelecem cronogramas de substituição de ferramentas de corte com base no tipo de material, volume de corte e requisitos de qualidade. Sistemas avançados máquina de corte de juntas frequentemente incorporam monitoramento do desgaste da ferramenta, fornecendo feedback em tempo real sobre o desempenho do corte. Esta tecnologia permite estratégias de manutenção preditiva que otimizam a vida útil da ferramenta, mantendo uma qualidade de corte consistente durante as corridas de produção.

Calibração e Alinhamento Semanal do Sistema

Verificação de Componentes Mecânicos

Os programas de manutenção semanais devem incluir a verificação abrangente do sistema mecânico para garantir a precisão operacional contínua. Esse processo envolve a verificação da tensão das correias, estado dos rolamentos e alinhamento do sistema de acionamento. A tensão adequada das correias evita deslizamentos, ao mesmo tempo que evita tensões excessivas que possam causar desgaste prematuro. A inspeção dos rolamentos identifica sinais precoces de deterioração, como ruídos incomuns, vibrações ou aumento de temperatura, indicando a necessidade de substituição.

O alinhamento do sistema de acionamento afeta a precisão de corte e a durabilidade dos componentes em toda a estrutura da máquina. Componentes desalinhados geram padrões irregulares de desgaste, aumento do consumo de energia e variações dimensionais nos produtos cortados. Procedimentos profissionais de alinhamento utilizam ferramentas de medição de precisão para verificar se todos os elementos mecânicos operam dentro das especificações do fabricante, assegurando desempenho ideal e vida útil prolongada.

Diagnósticos e Atualizações do Sistema de Controle

Sistemas modernos de corte de juntas incorporam tecnologias de controle sofisticadas que exigem avaliação diagnóstica regular e manutenção de software. Os procedimentos diagnósticos semanais devem verificar a precisão dos sensores, os tempos de resposta dos controles e a integridade da comunicação entre os componentes do sistema. Esses testes identificam possíveis problemas de controle antes que afetem a qualidade da produção ou causem paradas inesperadas de equipamentos.

Atualizações de software e verificação de parâmetros garantem que os programas de corte mantenham precisão para diferentes tipos de materiais e requisitos de produção. A calibração do sistema de controle inclui a verificação da precisão do feedback de posição, das características de resposta dos motores e do funcionamento do sistema de segurança. Procedimentos regulares de backup protegem programas críticos de corte e parâmetros da máquina contra perda de dados que possa interromper os cronogramas de produção.

Análise Mensal Abrangente do Sistema

Medição e Ajuste de Precisão

Ciclos mensais de manutenção proporcionam oportunidades para medições precisas detalhadas e ajustes do sistema que mantêm padrões de precisão a longo prazo. Esses procedimentos envolvem verificação dimensional abrangente utilizando equipamentos de medição de precisão para confirmar que as operações de corte atendem às tolerâncias especificadas. Quaisquer desvios em relação aos parâmetros estabelecidos exigem investigação imediata e ações corretivas para prevenir problemas de qualidade.

Os protocolos de ajuste do sistema abordam o desgaste acumulado e os efeitos ambientais que gradualmente impactam a precisão do corte. Equipes profissionais de manutenção utilizam sistemas de medição a laser, calibradores de precisão e equipamentos de medição por coordenadas para verificar a geometria da máquina e a precisão do corte. Essas medições orientam os procedimentos de ajuste que restauram as características de desempenho ideais e prolongam a vida útil do equipamento.

Controle Ambiental e Filtragem

Fatores ambientais influenciam significativamente o desempenho e os requisitos de manutenção da máquina de corte de juntas. A avaliação mensal da temperatura, umidade e níveis de contaminação no ambiente de trabalho ajuda a identificar condições que possam afetar a precisão do corte ou acelerar o desgaste dos componentes. O controle adequado do ambiente mantém condições operacionais estáveis que favorecem um desempenho consistente no corte.

Os sistemas de filtração de ar exigem inspeção e manutenção mensais para garantir um controle eficaz da contaminação. Filtros entupidos reduzem a eficiência do sistema e permitem que contaminantes atinjam componentes sensíveis da máquina. A substituição regular dos filtros mantém o fluxo de ar ideal, protegendo os mecanismos de corte contra poeira, detritos e outros contaminantes ambientais que possam comprometer a precisão operacional.

Desenvolvimento de Estratégia de Manutenção de Longo Prazo

Integração de Tecnologia de Manutenção Preditiva

Estratégias avançadas de manutenção incorporam tecnologias preditivas que monitoram o estado da máquina e prevêem necessidades de manutenção. A análise de vibração, o monitoramento de temperatura e a tendência de desempenho fornecem alertas precoces sobre problemas emergentes que poderiam afetar a precisão de corte ou causar falhas inesperadas. Essas tecnologias permitem que as equipes de manutenção programem reparos durante paradas planejadas, em vez de responderem a situações de emergência.

A integração de sistemas de monitoramento de condição com softwares de gestão de manutenção cria bases de dados completas de manutenção que acompanham o desempenho dos componentes, histórico de reparos e cronogramas de substituição. Essas informações apoiam decisões de manutenção baseadas em dados, otimizando a disponibilidade dos equipamentos ao mesmo tempo em que controlam os custos de manutenção. Abordagens de manutenção preditiva reduzem interrupções inesperadas e aumentam a eficácia geral dos equipamentos.

Gestão de Peças Sobressalentes e Controle de Estoque

A gestão eficaz de peças sobressalentes garante que componentes críticos permaneçam disponíveis para manutenção e reparos realizados em tempo hábil. O planejamento estratégico de estoque considera os prazos de entrega dos componentes, taxas de falha e criticidade para as operações de produção. Manter níveis apropriados de estoque de peças sobressalentes evita paradas prolongadas, ao mesmo tempo que evita custos excessivos de armazenagem.

Programas profissionais de manutenção estabelecem relacionamentos com fabricantes de equipamentos e distribuidores autorizados para garantir acesso a peças de reposição originais. Componentes de qualidade mantêm as características de desempenho do equipamento original, evitando problemas de compatibilidade que possam afetar a precisão de corte. A avaliação regular dos fornecedores assegura o acesso contínuo às peças necessárias e aos serviços de suporte técnico.

Requisitos de Treinamento e Documentação

Formação e certificação dos operadores

Programas abrangentes de formação dos operadores asseguram que o pessoal compreenda os procedimentos de manutenção adequados e reconheça os sinais precoces de problemas com os equipamentos. Os programas de formação devem abranger os procedimentos de inspecção diária, as técnicas de resolução de problemas básicas e os protocolos de segurança específicos das operações de corte de juntas. Os operadores bem treinados contribuem significativamente para a fiabilidade e qualidade do equipamento através de práticas de funcionamento e manutenção adequadas.

Os programas de certificação validam a competência do operador, estabelecendo simultaneamente a responsabilidade pela conformidade dos cuidados e manutenção dos equipamentos. A formação regular de actualização mantém o pessoal atualizado com as tecnologias em evolução e as melhores práticas de manutenção. A documentação da conclusão da formação apoia os sistemas de gestão da qualidade, assegurando simultaneamente que as actividades de manutenção cumprem as normas do sector e os requisitos regulamentares.

Documentação de manutenção e manutenção de registos

A documentação detalhada de manutenção fornece informações essenciais para solução de problemas, reivindicações de garantia e conformidade regulamentar. Os registros completos devem incluir resultados de inspeções, atividades de manutenção realizadas, peças substituídas e quaisquer problemas operacionais identificados. Essa documentação permite a análise de tendências que apoia a melhoria contínua da eficácia da manutenção e da confiabilidade dos equipamentos.

Os sistemas eletrônicos de gestão de manutenção agilizam os processos de documentação, ao mesmo tempo que fornecem acesso em tempo real ao histórico de manutenção e às informações de programação. Esses sistemas apoiam a conformidade com as normas de gestão da qualidade e facilitam a comunicação entre as equipes de manutenção e o pessoal de produção. Práticas adequadas de documentação contribuem para a excelência operacional geral e para a otimização dos equipamentos.

Perguntas Frequentes

Com que frequência as lâminas de corte devem ser substituídas nas máquinas de corte de juntas

A frequência de substituição da lâmina de corte depende do tipo de material, volume de corte e requisitos de qualidade. Os intervalos típicos de substituição variam de diários, em operações de alto volume que cortam materiais abrasivos, a semanais, em ambientes padrão de produção. Monitore o estado da lâmina por meio de inspeções regulares e substitua-a quando a qualidade da borda começar a afetar a precisão do corte ou a exatidão dimensional.

Quais são as causas mais comuns da perda de exatidão dimensional em equipamentos de corte de juntas

As causas comuns incluem ferramentas de corte desgastadas, desgaste mecânico nos sistemas de guia, flutuações de temperatura ambiental e calibração inadequada da máquina. A manutenção adequada, abordando esses fatores por meio de inspeção regular, calibração e substituição de componentes, mantém a precisão ideal de corte durante toda a vida útil do equipamento.

Como as condições ambientais podem afetar o desempenho da máquina de corte de juntas

Variações de temperatura causam expansão e contração térmica que afetam a precisão dimensional, enquanto a umidade pode impactar as propriedades dos materiais e as características de corte. Poeira e contaminação aceleram o desgaste dos componentes e afetam a qualidade do corte. Manter condições ambientais estáveis por meio de um projeto adequado das instalações e sistemas de filtração otimiza o desempenho da máquina e prolonga sua vida útil.

Quais considerações de segurança são essenciais durante a manutenção de máquinas cortadoras de juntas

As práticas essenciais de segurança incluem procedimentos adequados de bloqueio/etiquetagem, uso de equipamentos de proteção individual e verificação do funcionamento dos sistemas de segurança. A equipe de manutenção deve ser treinada sobre os riscos específicos do equipamento e sobre procedimentos de emergência. Testes regulares do sistema de segurança garantem proteção contínua para operadores e técnicos durante operações rotineiras e atividades de serviço.

Sumário

- Procedimentos Essenciais de Manutenção Diária

- Calibração e Alinhamento Semanal do Sistema

- Análise Mensal Abrangente do Sistema

- Desenvolvimento de Estratégia de Manutenção de Longo Prazo

- Requisitos de Treinamento e Documentação

-

Perguntas Frequentes

- Com que frequência as lâminas de corte devem ser substituídas nas máquinas de corte de juntas

- Quais são as causas mais comuns da perda de exatidão dimensional em equipamentos de corte de juntas

- Como as condições ambientais podem afetar o desempenho da máquina de corte de juntas

- Quais considerações de segurança são essenciais durante a manutenção de máquinas cortadoras de juntas

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES